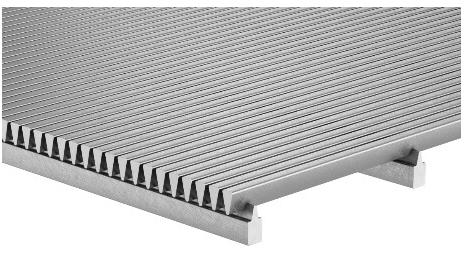

Wedge wire, also known as profile bar or Vee-Wire, is a specialized screen wire characterized by its unique wedge-shaped profile. This v-shaped design is crucial for fabricating high-performance screens across many industries and applications.

As a leading provider of wedge wire solutions, we understand the critical role these screens play in optimizing various processes.

What is Wedge Wire?

Wedge wire screens are engineered for superior performance and durability. They are fundamentally a type of screen wire, representing a family of precisely shaped materials used in screen manufacturing. The key to their effectiveness lies in the wedge-shaped profile of the wire. This shape allows for a larger open area compared to traditional woven wire meshes, facilitating efficient flow while effectively retaining solids.

Our commitment to quality begins with sourcing only the highest-grade raw materials. These materials are then transformed into a variety of screen components, including water nozzles, filter pipes, tubes, cylinders, baskets, resin traps, and more. We utilize advanced manufacturing techniques, encompassing both loop and welded technologies, to ensure precision and consistency in every product. This rigorous process guarantees screens that meet the most demanding specifications.

Diverse Wire Screen Forms for Varied Applications

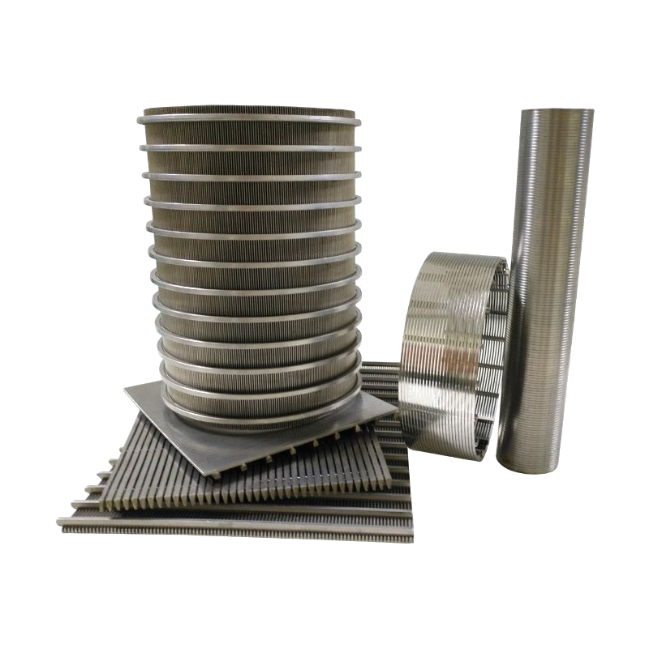

Wedge wire screens are incredibly versatile, and their adaptability is reflected in the various forms they can take. Depending on the specific application and functional requirements, wedge wire screens can be manufactured in several configurations, including:

Cylindrical Screens: Ideal for applications requiring high flow rates and efficient solid-liquid separation.

Flat Screens: Well-suited for gravity-fed systems and applications where a flat surface is needed for material distribution.

Tube Screens: Designed for applications requiring precise filtration and structural integrity.

This flexibility allows us to tailor solutions to meet the unique needs of our clients.

Where and How is Wedge Wire Used?

The unique design and robust construction of wedge wire screens makes them indispensable across a wide spectrum of industries. Some of the most common applications include:

Water Filtration: Removing suspended solids, debris, and other contaminants from water sources to ensure clean and safe water for various purposes, from drinking water treatment to industrial processes.

Mineral Processing: Separating and classifying minerals based on size, crucial for maximizing recovery and efficiency in mining operations.

Pulp and Paper Manufacturing: Filtering pulp slurries to remove impurities and fibers, resulting in higher quality paper products.

Food Processing: Screening and separating food products to remove unwanted particles, ensuring product purity and safety.

Oil Extraction: Separating sand, gravel, and other solids from crude oil, protecting downstream equipment and optimizing oil production.

Architecture: Increasingly used for architectural facades, providing unique aesthetic appeal while offering functional benefits like shading and ventilation.

Constructing a High-Performance Wedge Wire Screen

The creation of a functional wedge wire screen involves a carefully considered assembly process. After the wedge wire itself is fabricated, it must be securely supported. This support structure can consist of round or screen wire, or even a solid strip or sheet, depending on the specific application and design requirements. The support provides the necessary structural integrity to withstand pressure and maintain the desired gap between the wedge wires.

Dominant Screen Types: Flat vs. Cylindrical

As mentioned, the two most prevalent types of wedge wire screens are flat and cylindrical. However, within the cylindrical category, further variations exist:

Flat Screens: These are primarily used for static applications where a horizontal screening surface is required.

Cylindrical Screens: These can be further categorized into:

Tube Screens: Featuring a cylindrical shape for radial flow.

Basket Screens: Designed with a closed bottom, typically used for vertical filtration.

Why Choose Us for Your Wedge Wire Screen Needs?

We are committed to providing superior wedge wire screen solutions that meet the highest standards of quality and performance. Our expertise extends beyond simply manufacturing screens; we offer comprehensive support to help you select the optimal screen design for your specific application.

Here's what sets us apart:

Unwavering Commitment to Quality: We use only the finest raw materials and employ rigorous quality control measures throughout the manufacturing process.

Advanced Manufacturing Techniques: We leverage cutting-edge technologies, including both loop and welded construction methods, to ensure precision and durability.

Customized Solutions: We offer a wide range of screen forms and configurations to meet the unique needs of each client.

Expert Support: Our team of experienced engineers and technicians can provide expert guidance on screen selection, installation, and maintenance.

Exceptional Customer Service: We are dedicated to providing responsive and reliable support to ensure your complete satisfaction.

Wedge wire screens are a versatile and essential component in numerous industrial applications. Their unique design, combined with their robust construction, allows for efficient and reliable separation, filtration, and classification. By choosing us as your wedge wire screen provider, you can be confident that you are investing in a high-quality product that will optimize your processes and enhance your operational efficiency.

Contact us today to learn more about our wedge wire solutions.

Contact us today at:

Email: admin@yuanlvfilter.com