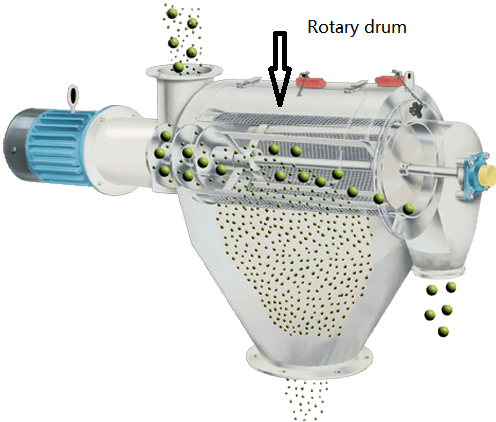

Wedge wire rotary drum screens, also known as rotary sifters, are important filter elements in both municipal and industrial wastewater treatment processes.

Positioned as a crucial second pre-treatment step, typically following the initial screening, rotary drum screens play a vital role in safeguarding downstream equipment and enhancing the overall efficiency of wastewater treatment plants. Located strategically upstream, often at the discharge point of the wastewater collection pumping station, these screens are designed to remove fine and coarse debris, ensuring optimal performance in subsequent treatment stages.

The Importance of Fine Screening

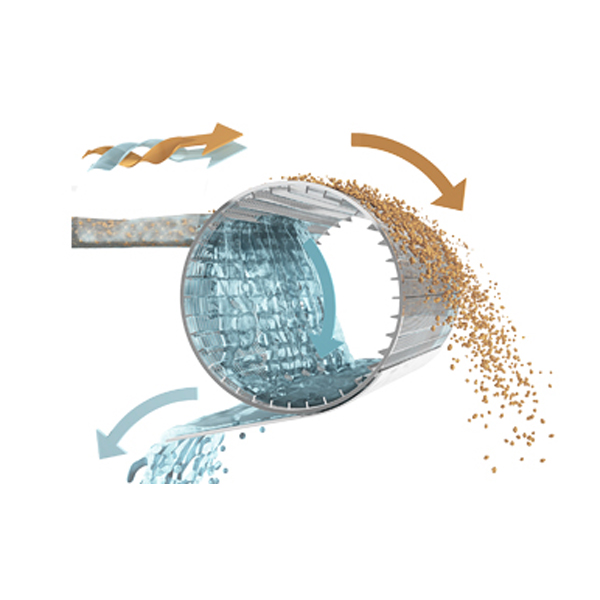

Rotary drum screens are highly sought-after for the fine treatment of both industrial and domestic wastewater. Their effectiveness in removing even complex fibrous impurities like wool and hair makes them an ideal solution for small- to medium-capacity wastewater treatment plants. By preventing these materials from interfering with downstream processes, rotary drum screens contribute significantly to the overall efficiency and reliability of the plant.

Key Features and Benefits of Rotary Drum Screens

Efficient Debris Removal: Rotary drum screens effectively capture mechanically fine and coarse debris, including trash rack debris (RAG), thick sands, and grease. This prevents waste from mixing with sludge, interfering with downstream processes, and potentially damaging equipment.

Fine Screening Capability: These screens offer fine screening capabilities based on the selected mesh size, with commonly used sizes ranging from 1 mm. This precise filtration ensures the removal of even small particles, enhancing the quality of the treated wastewater.

Compact and Energy-Efficient Design: The closed design and high capacity of rotary drum screens, all within a compact enclosure, make them an energy-efficient solution for modern wastewater treatment plants.

Odor Control: The fully enclosed design of some rotary drum screens prevents the spread of unpleasant odors and potentially dangerous gases, contributing to a safer and more pleasant working environment.

Two Primary Types of Rotary Drum Screens

While the core function remains the same, rotary drum screens are typically manufactured in two primary configurations:

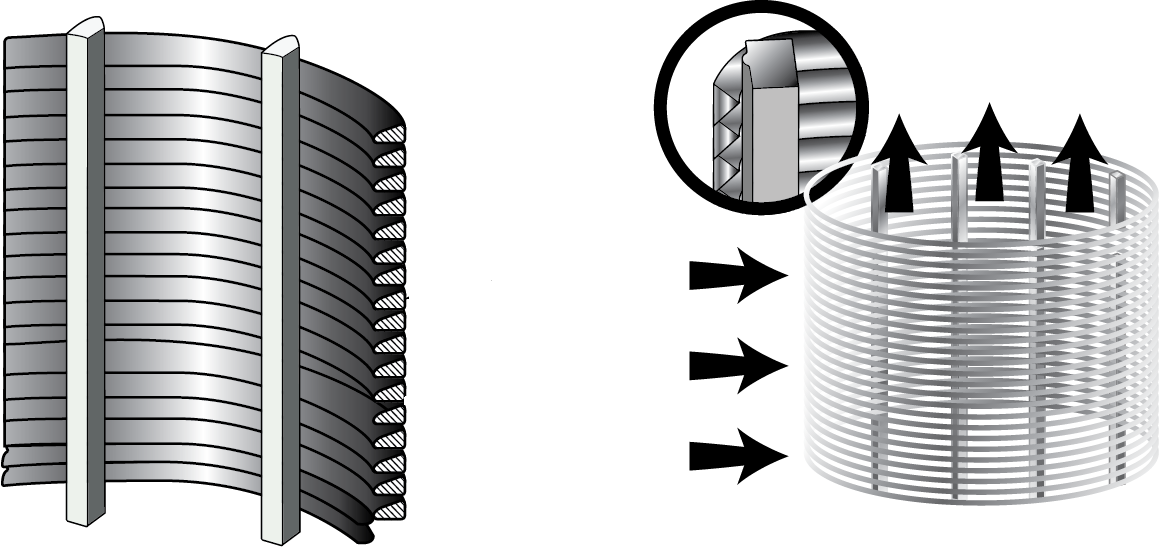

With Wedge Wire Screen: Wedge wire drum screens are highly regarded for their superior performance and offer several key advantages.

With Perforated Metal Sheet: Perforated metal sheet drum screens provide a cost-effective solution for certain applications.

The Advantages of Wedge Wire Drum Screens

Wedge wire drum screens offer three significant benefits that contribute to their widespread adoption:

Optimal Transition Coefficient: The design promotes efficient flow and throughput.

Self-Cleaning Profile: The wedge shape allows fine particles to slide through without blocking the slots, minimizing clogging and reducing maintenance requirements.

Odor Control: A fully enclosed design prevents the escape of unpleasant odors and potentially harmful gases.

Diverse Applications Across Industries

Wedge wire drum screen filters are widely utilized in various activities, including:

Wastewater Pretreatment: Essential for both municipal and industrial wastewater treatment to remove solids and protect downstream equipment.

Wastewater Treatment with High Solids Content: Effectively manages wastewater containing high concentrations of solids, including fibers, wool, feathers, and films.

Effluent Treatment in Specific Industries: Ideal for paper mills, textile industries (dyeing and bleaching), chemical and pharmaceutical industries.

Industrial and Domestic Wastewater Treatment Plants: Providing reliable and efficient screening for a wide range of applications.

Membrane Bioreactor (MBR) Treatment Plants: Highly recommended as a crucial pre-treatment step for MBR systems, protecting the sensitive membranes from damage and fouling.

The Crucial Role of Screening in Wastewater Treatment

Screening is a fundamental step in wastewater treatment, removing large waste materials that could interfere with the effectiveness of subsequent treatments. It protects plant structures from damage caused by large objects in the wastewater flow, ensuring the longevity and reliability of the entire system.

Protecting Downstream Processes

Screening wastewater treatment plant effluent is critical because it removes debris, preventing large waste from contaminating sludge and protecting downstream processes. Rotary drum screens minimize pump clogging and reduce crusting in primary clarifiers. This is particularly important when downstream processes involve filters, ensuring their efficient operation and longevity.

YUANLV: Your Partner for Rotary Drum Screen Solutions

YUANLV is a leading manufacturer of wastewater treatment rotary drum screens, providing filters tailored to your specific project requirements. Our commitment to quality and innovation ensures that our rotary drum screens deliver exceptional performance, reliability, and efficiency.

Contact us today to discuss your needs!