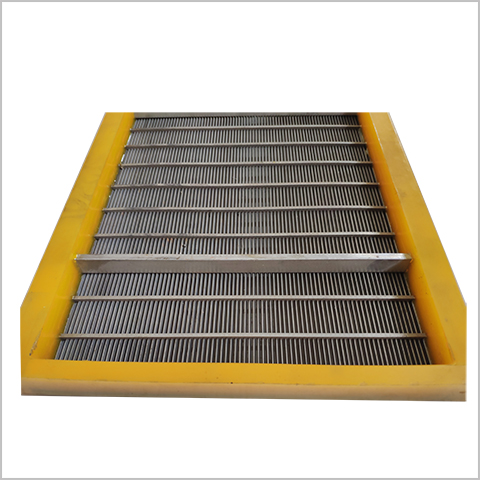

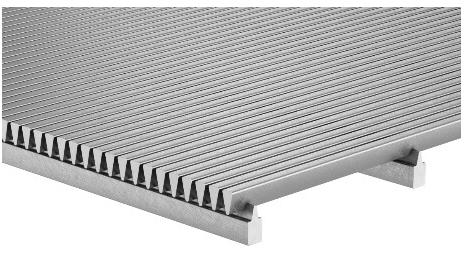

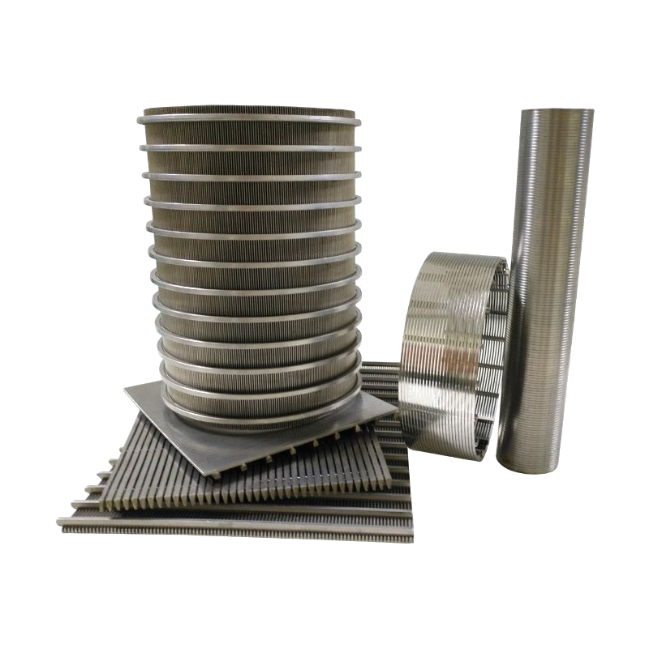

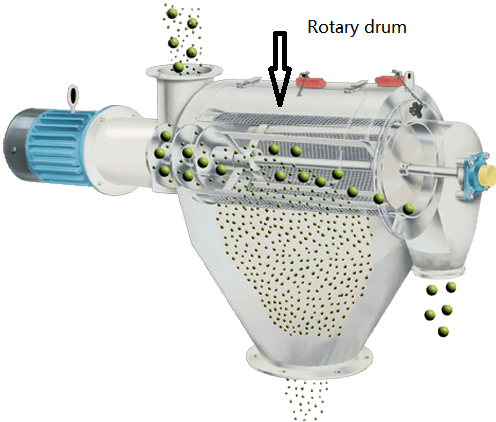

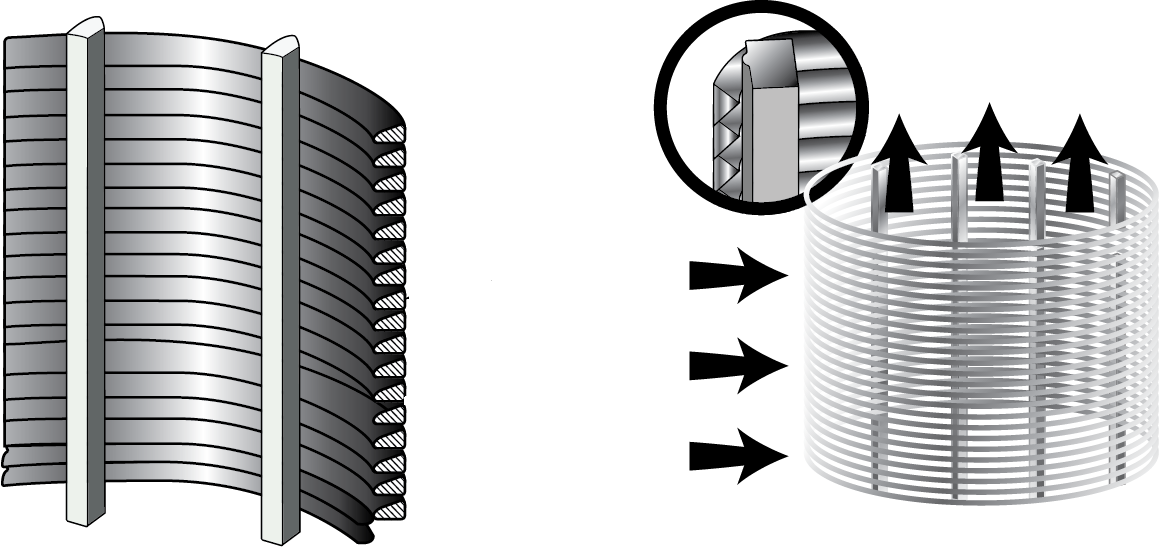

Wedge wire screen collector/distributor systems are critical internal components in various vessels. They are renowned for their exceptional strength, durability, and ability to deliver uniform flow distribution. These wedge wire collector systems are vital in optimizing the performance of ion exchange units, media filters, sand filters, carbon strip vessels, carbon towers, clay filters, and a wide range of water and wastewater treatment applications.

Key Features and Benefits:

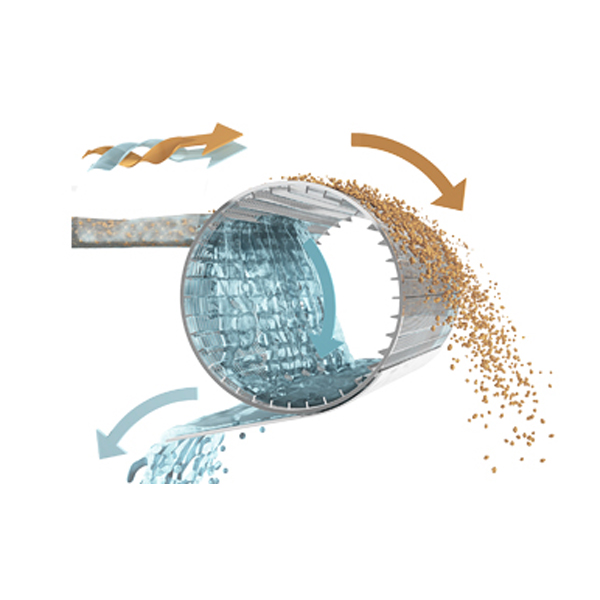

Even Flow Distribution: Wedge wire screens ensure a consistent and even flow distribution, maximizing the efficiency of treatment processes.

Exceptional Strength and Durability: The robust construction of wedge wire screens, coupled with the use of high-quality materials, guarantees long-lasting performance and resistance to demanding conditions.

Versatile Configurations: Available in both header-lateral and hub-lateral assemblies, offering flexibility to suit diverse vessel designs and application requirements.

Flexible Connection Options: YUBO's wedge wire screen laterals and pipe-based laterals can be seamlessly integrated with distributor headers and spider hubs using standard NPT threads, fabricated flanges, ANSI connections, or fully welded assemblies.

Multi-Tiered Designs: Wedge wire hub lateral systems can be configured with multiple tiers of wedge wire screen laterals to optimize collection and distribution in specific applications.

Header Lateral Systems for Large Filters: Header lateral systems are ideal for larger-diameter filters, providing efficient collection across the entire filter bed.

Enhanced Backwash with Perforated Pipe Distributor: A perforated pipe distributor can be added to header lateral systems to improve backwash distribution and further enhance the system's overall strength and durability.

Superior Construction for Demanding Applications:

The unique internal support-rod structure, combined with the availability of various materials, including stainless steel and other alloys, makes wedge wire an excellent choice for constructing robust and reliable underdrain systems. This adaptability ensures that the system can withstand the rigors of even the most demanding applications.

Ideal for a Broad Range of Industries:

Wedge wire screen collector/distributor systems are widely used across various industries, including:

Water Treatment: Ensuring efficient filtration and treatment of potable water.

Wastewater Treatment: Removing contaminants and pollutants from industrial and municipal wastewater.

Oil & Gas: Separating solids and liquids in oil and gas production processes.

Power Generation: Filtering water used in cooling towers and other power generation systems.

Food & Beverage: Removing impurities and ensuring the quality of food and beverage products.

Mining: Separating valuable minerals from ore and tailings.

Pharmaceutical: Ensuring the purity and quality of pharmaceutical products.

Pulp and Paper: Filtering process water and recovering fibers in pulp and paper mills.

By choosing wedge wire screen collector/distributor systems, industries can optimize their processes, improve product quality, and reduce operational costs.

Their strength, durability, and customizable design make them a vital component for a wide range of applications.

YUBO is the wedge wire collector/distributor systems manufacturer &exporter in China, we can customize the drawing design as per your project's requirements.

+86 180 3215 3916