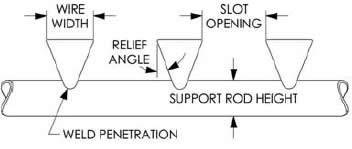

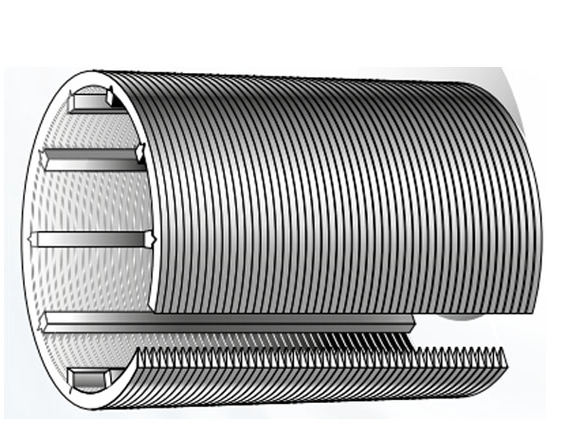

The wedge wire screen is a metal mesh element widely used in screening, filtration, dehydration, and desliming operations for sieving and filtration. Crafted through precise welding of V-shaped profiles onto support profiles at designated intervals, these screens boast continuous gaps that efficiently filter liquids while entrapping larger substances. Their versatility and varied applications make them vital in numerous industries, ensuring optimal performance in sieving and filtration operations.

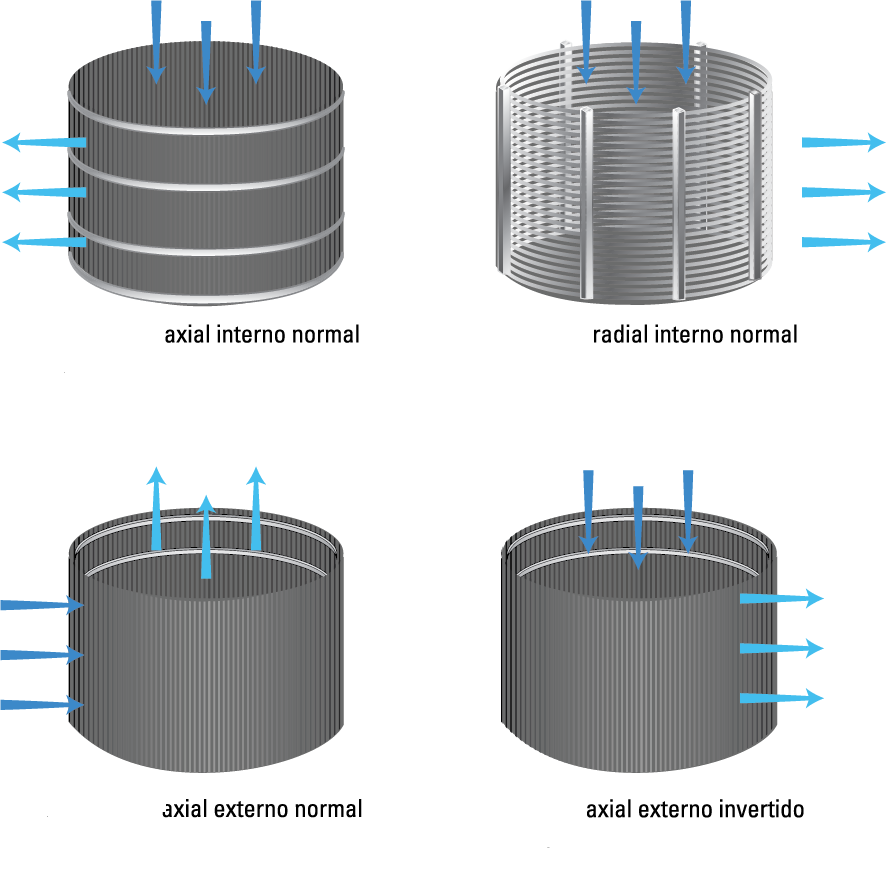

Wedge Wire Screens Flowing Direction:

Wedge wire screens present diverse flowing directions crucial for specific applications--FOTI (Flowing Outside to Inside) and FITO (Flowing Inside to Outside)

Types of Wedge Wire Screen:

-Radial External Wedge Wire:

--FOTI: Ideal for standard applications with precision openings and cost-effective production.

--FITO: Offers reversed flow, beneficial for backwashing procedures.

- Radial Internal Wedge Wire:

--Only available in FITO, this type enables a smooth internal screen surface, facilitating cleaning and proving economical for small-quantity productions.

- Axial Internal and External Wedge Wire Variants:

Different constructions providing distinct advantages such as smooth surfaces, effective dewatering, and enhanced strength.

Wedge Wire Screen Open Area Calculation:

Determining the open area percentage proves crucial in predicting flow capacity,

Open Area = ( Slot Opening / (Wire Width + Slot Opening)) × 100

Diverse Application Category of Wedge Wire Screens:

The utility of wedge wire screens spans various domains:

Filtration Elements: Essential components in filtration devices for particle and liquid filtration.

Intake Screens: Safeguarding intake systems, particularly in seawater purification.

Mining Screens: Efficiently grading and separating mines and materials in mining equipment.

Wedge wire Support Grids: Installed at the bottom of the carbon filters, desulfurizers, molecular sieves, and sand lauter tanks for support and filtration.

Sieve Bends: Mainly installed in sieve bend screens. It is the main filtering part of the screen.

Nozzles: Installed at the bottom of sand filters or mixed beds for particles and liquid filtration.

Centrifuge Baskets: Integral parts in diverse filtration systems for support, filtration, and solid-liquid separation. Most in the coal mine and pulppaper industry.

Lateral Assemblies and Resin Traps: Installed in mixed beds for particles and liquid filtration or the bottom of sand filters or mixed beds for particles and liquid filtration.

Rotary Drum Screens: Key components ensuring effective particle and liquid filtration across different setups.

Advantages of Wedge Wire Screens:

These screens boast numerous benefits, including high strength, maximum flow rates, anti-clogging slots, adaptability to temperature fluctuations, exceptional corrosion resistance, and customizable sizes.

Order Wedge Wire Screen Products Quickly, please read the FAQ articles

In conclusion, the unparalleled efficiency and adaptability of wedge wire screens across a spectrum of industries make them indispensable components in modern filtration and separation processes, offering reliability and precision in diverse applications.

Contact Us

If you need to consult the price, please contact the business department by E-mail: admin@yuanlvfilter.com