Wedge wire filters are considered one of the most dependable products when it comes to filtration and has been used in various industrial processes. Many industries depend on the filters not only due to the material grade but also with precision in filtering and longer life.

Wedge wire filters are widely used in various industries for their reliability and efficiency in filtration.

Here are some recommended wedge wire filters for different industrial applications:

Food and Beverage Industry

Wedge wire screens are integral in food and beverage manufacturing, offering specific features tailored to withstand pressure, facilitate efficient extraction and filtration, resist clogging, and ensure easy maintenance. Slotted wedge wire screens, with precise gap sizes, allow uniform passage of food products. In the beverage sector, wedge wire tube cylinders effectively separate solids from liquids, employing a spiral design to extract juices while preventing solid ingress into the filtration process.

Sewage and Waste Water Treatment

Easily found in sewage and wastewater treatment plants, wedge wire screens efficiently filter out solid particles from liquid, achieving a 99.99% removal rate in the initial stage, significantly enhancing solid waste removal efficiency. Their uniform mesh filters ensure easy removal of solid materials without causing clogging. Some plants enhance wedge wire filters with stainless steel coatings to prolong their lifecycle and durability in such environments.

Refinery and Petrochemical Industry

Vital in the petrochemical sector, these screens aid chemical processing, media retention, de-sulfuring, and hydro-treating procedures. Centrifugal baskets and screen support grids offer accurate particle separation while reinforcing mesh with abrasive coatings ensures resilience against chemical exposure.

Mineral Processing Industry – Iron, Ore, Coals

Wedge wire screens' ability to withstand pressure makes them indispensable in mineral processing. They effectively separate minerals from crushed stones, handling substantial volume and weight pressures. Perforated metal sheets or slotted screens further filter and segregate minerals, while centrifuge baskets endure high levels of vibration and rotational stress during the separation process.

Pulp and Paper Industry

Fine wedge wire screens facilitate dewatering, fiber retention, pulp separation, and efficient wastewater treatment in this sector. Pressure screens and sieve bends enhance separation efficiency, with the latter requiring minimal structural support and space for installation while ensuring quiet operation.

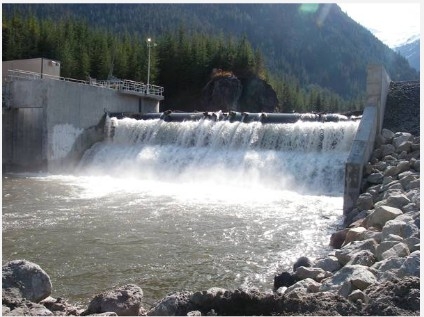

Seawater Purification

Intake Screens installed at seawater purification intakes protect fish species from harmful debris while safeguarding pumps and turbines.

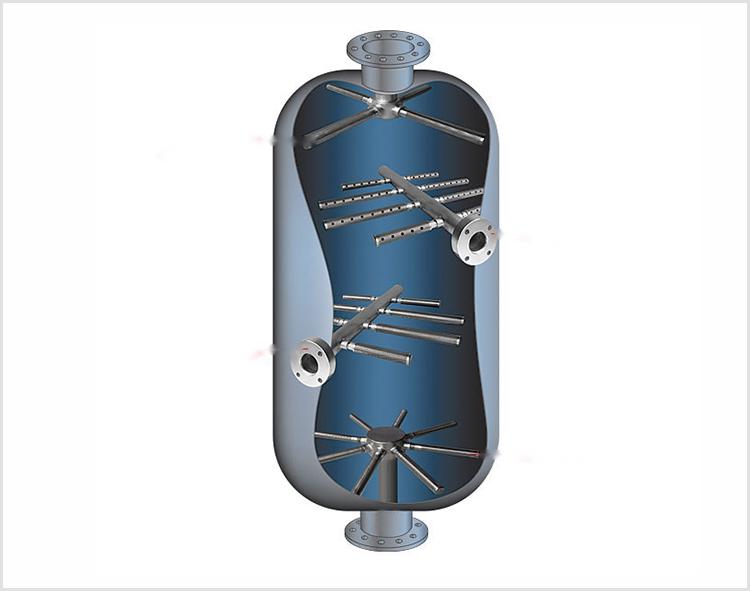

Sand Filter Industry

Wedge Wire Screen Support Grids are installed at the bottom of carbon filters, desulfurizers, molecular sieves, and sand lauter tanks for support and filtration. Wedge Wire Nozzles are used in sand filters or mixed beds to filter particles and liquids.

Rubber Plants Industry

A vibrating screen with perforated stainless steel plates is used to separate granulated natural rubber from process water in rubber plants.

Aesthetic and Architectural Applications

Beyond industrial use, stainless steel wedge wire screens find popularity for their aesthetic appeal. They serve as floor panel grates for heat or water release, architectural facades, balustrades, flooring grates, and partitions, owing to their durability, corrosion resistance, and ease of maintenance.

These recommended wedge wire filters highlight their versatility and effectiveness in various industrial applications.

Welcome to our Wedge Wire filter factory. Here you will find useful documentation and information on our Wedge Wire product uses for industry and market sectors.

For more industry Recommended Wedge Wire products, please Email us: at sales@ubooem.com