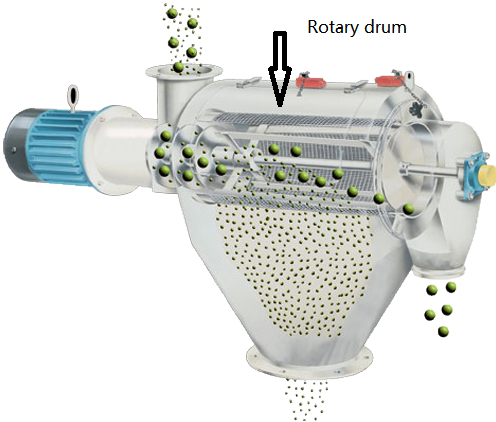

Rotary drum screens, also known as rotary sifters, play a pivotal role in municipal and industrial water treatment processes. Positioned as the second pre-treatment step after initial screening, these devices are typically placed upstream from the main system, specifically at the discharge point of the wastewater collection pumping station.

Rotary drum screens are adept at collecting both mechanically fine and coarse debris, including trash rack debris (RAG), thick sands, and grease, making them indispensable in maintaining the integrity of wastewater treatment plants.

Fine Separation with Rotary Drum Screens:

The primary function of the rotary drum screen lies in its ability to perform fine screening based on the chosen mesh size.

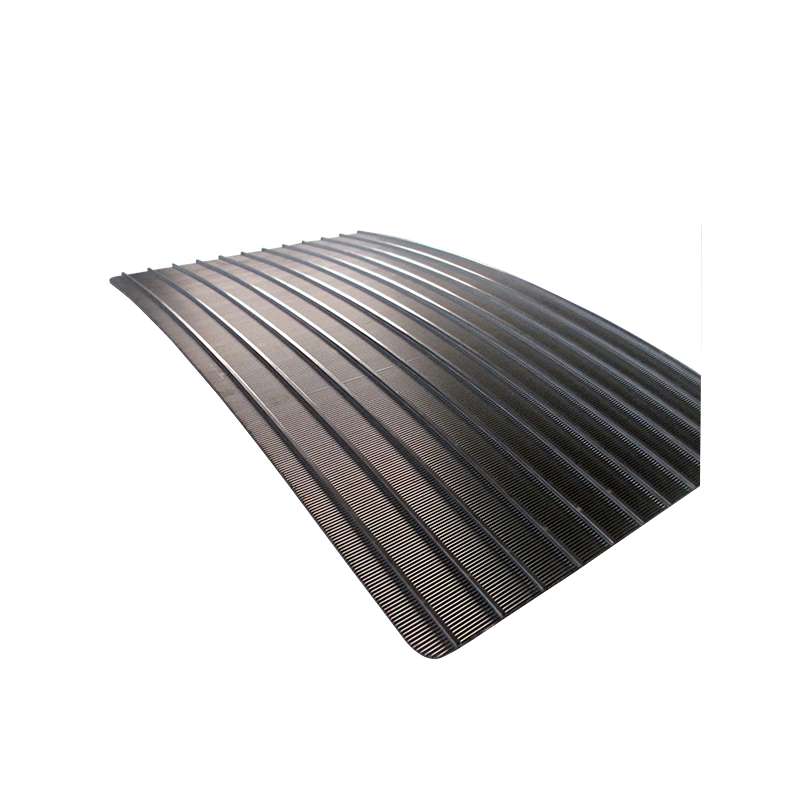

There are two prevalent types of rotary drum screens - those with triangular wire and those with perforated metal sheets.

Triangular V wire drum screens offer distinct advantages, including an optimal transition coefficient and a shape that facilitates the unimpeded passage of fine particles without causing slot blockages. This stands in contrast to flat plates, which have a rough side due to the manufacturing process.

Rotary Drum Screen vs. Rotary Screen:

While the terms are often used interchangeably, there is a subtle distinction between "rotary drum screen" and "rotary screen." The former is associated with the separation of solids and liquids, typically applied in wastewater treatment, while the latter refers to equipment designed for the separation of solids from other solids, such as in composting processes.

Applications of Rotary Drum Screens:

The versatility of rotary drum screens extends to various applications, making them suitable for special scenarios requiring fine screening. Notable uses include wastewater treatment, where the drum screen serves as the initial pre-treatment step before primary treatment or flotation. Screening wastewater treatment plant effluent is crucial for debris removal, preventing large waste in the sludge and safeguarding downstream processes, including the use of filters. Additionally, the implementation of a drum screen reduces pump clogging and minimizes crust formation on primary clarifiers.

Screening and Rotary Drum Screens in Concert:

An effective combination often found in large wastewater treatment plants involves the integration of a coarse screener to protect pumps at the pumping station, followed by a rotary drum screen for refined filtration at the discharge point.

Case Studies:

South Africa: Implementation of Rotary Drum Screen in Wastewater Treatment.

Chile: Utilization of Rotary Drum Fines Screen in Municipal Wastewater Treatment.

These case studies highlight the global applicability of rotary drum screens in diverse wastewater treatment scenarios.

Typical Applications:

Rotary drum screens find application in various industries and processes, including:

--Separation of solids and sludges in municipal and industrial wastewater.

--Filtration in food processes.

--Pulp and paper production.

--Rendering processes.

--Removal of extruded pellets from cooling baths.

--Debris separation in plant and equipment-cleaning processes.

Rotary drum screens emerge as indispensable components in wastewater treatment, ensuring efficient debris removal, protection of downstream processes, and prevention of equipment issues. Their adaptability and effectiveness make them a cornerstone in achieving successful and sustainable water treatment practices across different industries globally.