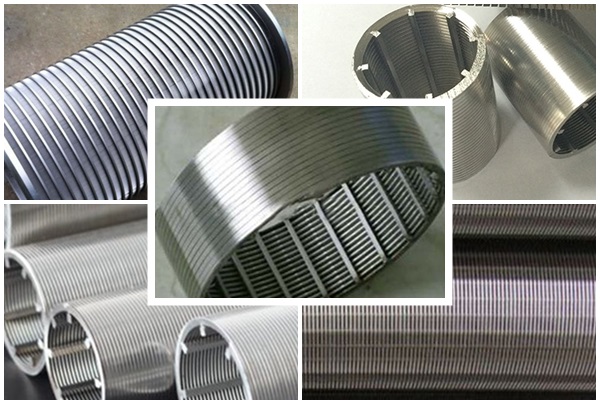

Rotating Sieve Screens is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding.

APPLICATION FOR ROTATING SIEVE SCREENS:

widely used in mineral processing,coal processing,food processing,water treatment,petrochemical industry,architecture industry, as well as many other applications involving liquid & solids separation.

FEATURES FOR ROTATING SIEVE SCREENS:

1.Continuous opening has greatly increased the water flow area, so offers a better contact with the aquifer.

2. V-type profile of the structure to avoid clogging and ensure smooth flow.

3. Continuous long-term effective use of the pore.

4. Trapezoidal filter pipe offers a solid structure, high porosity, and accurate poring.

5. Trapezoidal wire filter pipe is easy for washing, long service life, safe, reliable, comprehensive and low cost.

ADVANTAGES FOR ROTATING SIEVE SCREENS:

1.Screens with high open area are more suitable for the construction of high-quality water wells and gas wells.

2.Low cost operation.

3.Reduce the abrasion of the pump.

4. Extend the life span of wells, low-carbon, Galvanized or stainless steel construction

CONSTRUCTION FOR ROTATING SIEVE SCREENS:

1.We use wedge-shaped profile wire in order to make the slot v-shaped. It can stop the impurities very well.

2.The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the screen have bigger filter area and non obstructive, avoid the high concentration of impurities.

3.After work for a period of time, the filter can be back flush.It can use for many times.

SPECIFICATION OF THE ROTATING SIEVE SCREENS

size | inner diameter | outer diameter | |||

IN | MM | IN | MM | IN | MM |

2 | 51 | 2 | 51 | 25/8 | 67 |

3 | 76 | 3 | 76 | 35/8 | 92 |

4 | 102 | 4 | 102 | 45/8 | 117 |

5 | 127 | 5 | 127 | 55/8 | 143 |

6 | 152 | 6 | 152 | 65/8 | 168 |

8 | 203 | 8 | 203 | 85/8 | 219 |

10 | 254 | 10 | 254 | 103/4 | 273 |

12 | 305 | 10 | 305 | 123/4 | 324 |

PRODUCTION AND SALES OF ROTATING SIEVE SCREENS