YUBO-Exceptional Wedge Wire Filter Manufacturing Expert in China

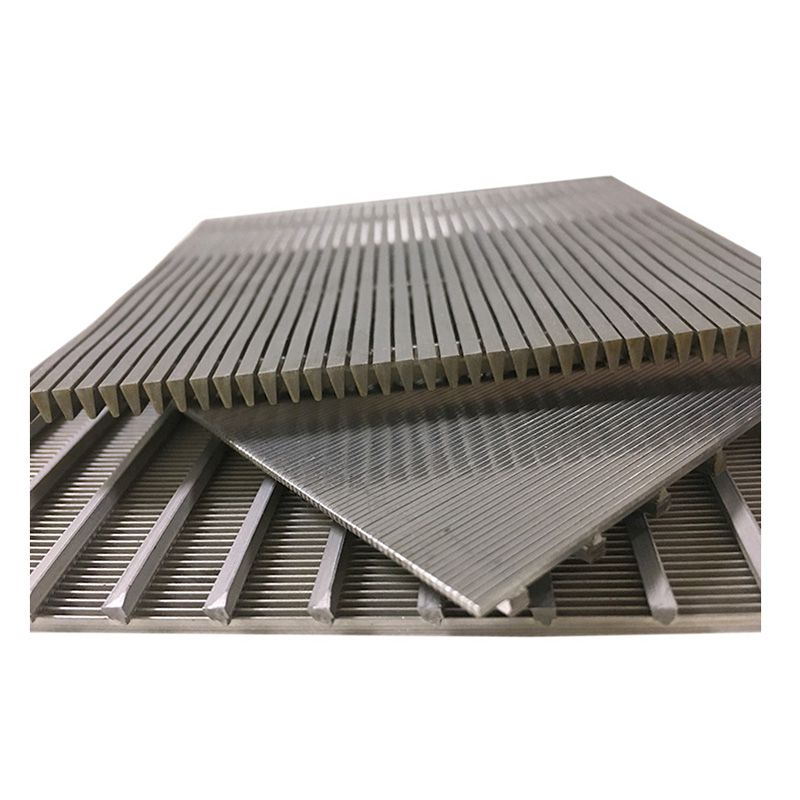

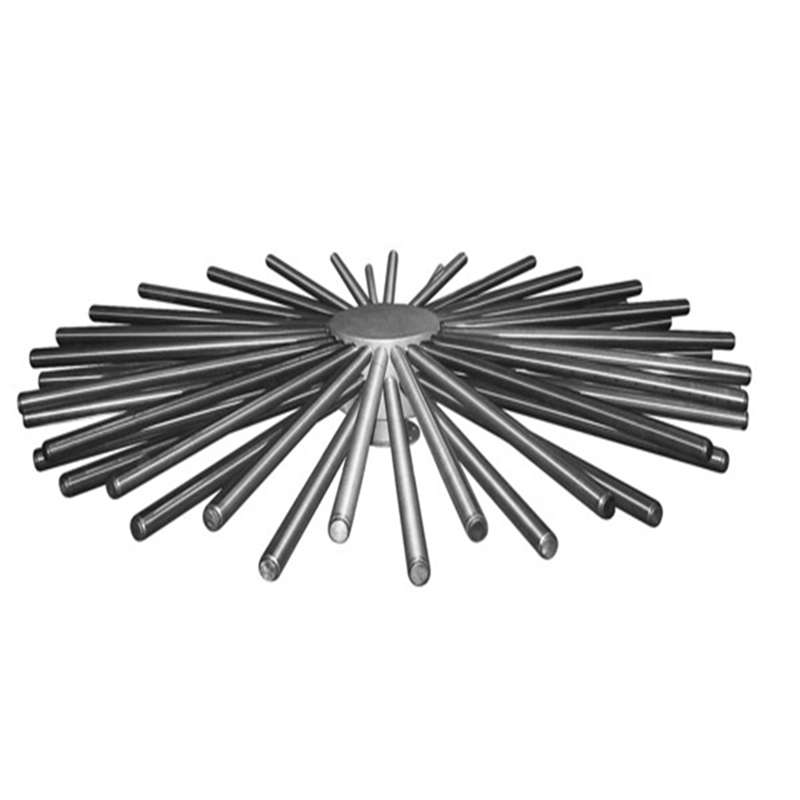

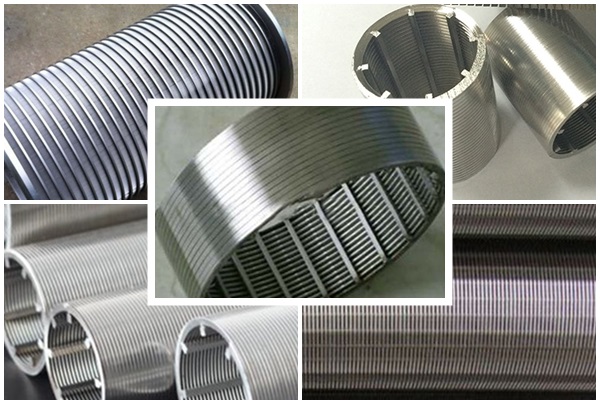

YUBO not only provide industry filter housings, but also supplies numerous shapes of wedge wire filter strainers, like wedge wire basket, wedge wire tube, and wedge wire cylinder.

The wedge wire filter screen can use for filter elements for filter equipment and is also used in the industrial filtration process.

If your process involves any aspect of solid-liquid separation, dewatering, or liquid distribution, we really recommend choosing our wedge wire filters. You can use wedge wire filter screens in the electric power industry, natural gas well, paper making, environmental protection, and control and water treatment.

Wedge Wire Filter

Each unit is designed to suit the requirements of the customer as well as the application, enabling a low-cost solution for separating solids and also liquids.

Why Choose YUBO?

YUBO is a manufacturer &exporter that owns a complete production line and expert engineers. We have already done business in the filtration field for over 10 years, so you can be assured to be our partner.

YUBO always provides OEM service for you to satisfy your specific filtration needs. You can tell us your application, requirements, and parameters of your system, then our professional engineer will give you a perfect solution.