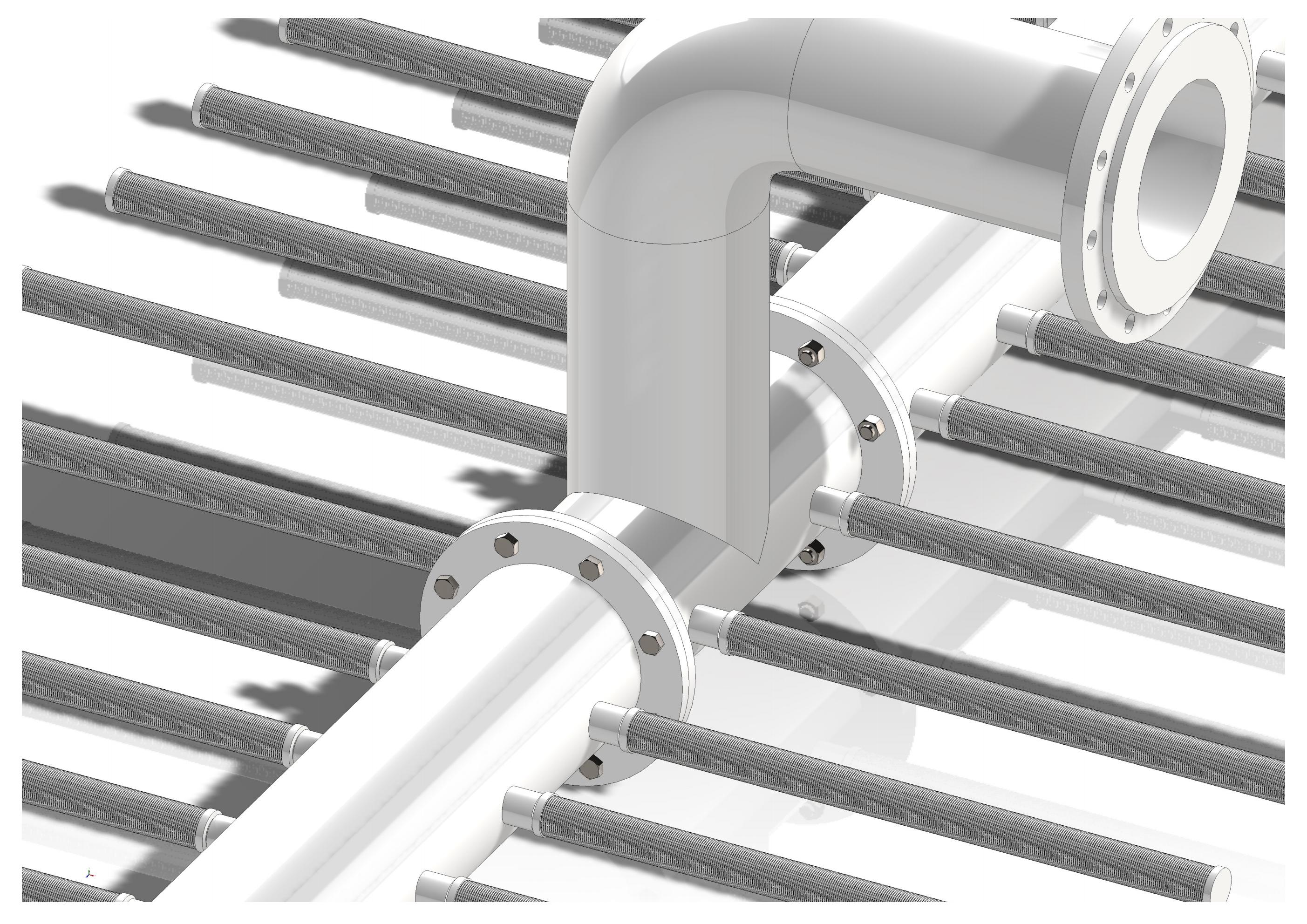

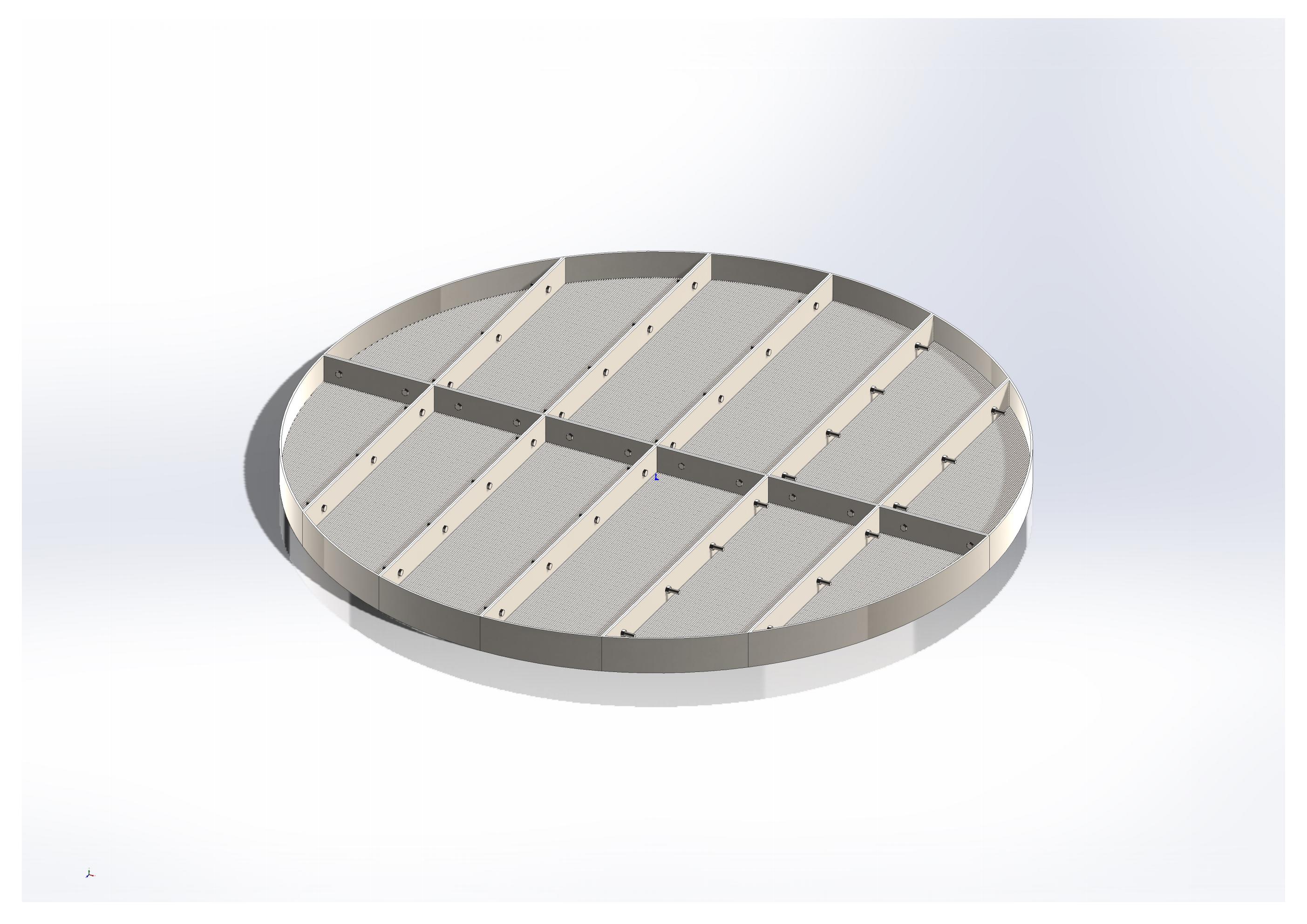

Mash tun floors are removable plates used in the mash tun, it has two functions:

--Support the mash bed.

--Filter the wort as it flows through.

There are two types of mash tun floors: perforated type, and wedge wire screen type.

YUANLV provides wedge wire type customized services for global customers.

Wedge Wire Mash Tun Floors for Enhanced Brewing Efficiency.

Optimize Your Brewery with Wedge Wire Screen Floors for Mash Tuns

In the intricate process of beer production, where malted barley grains are ground and mixed with hot water to activate enzymes, precision is paramount. As starches convert into sugar, the resulting solution must be meticulously filtered before transferring into a vessel for further processing. This is where the importance of a reliable filtration system comes into play.

Traditionally, brewery mash tuns have relied on perforated metal plates to act as a filter at the vessel's base. However, many brewers encountered challenges with this setup. Issues such as difficulty in emptying the vessel and unclear runoff plagued their brewing process, hindering efficiency and affecting the quality of the final product.

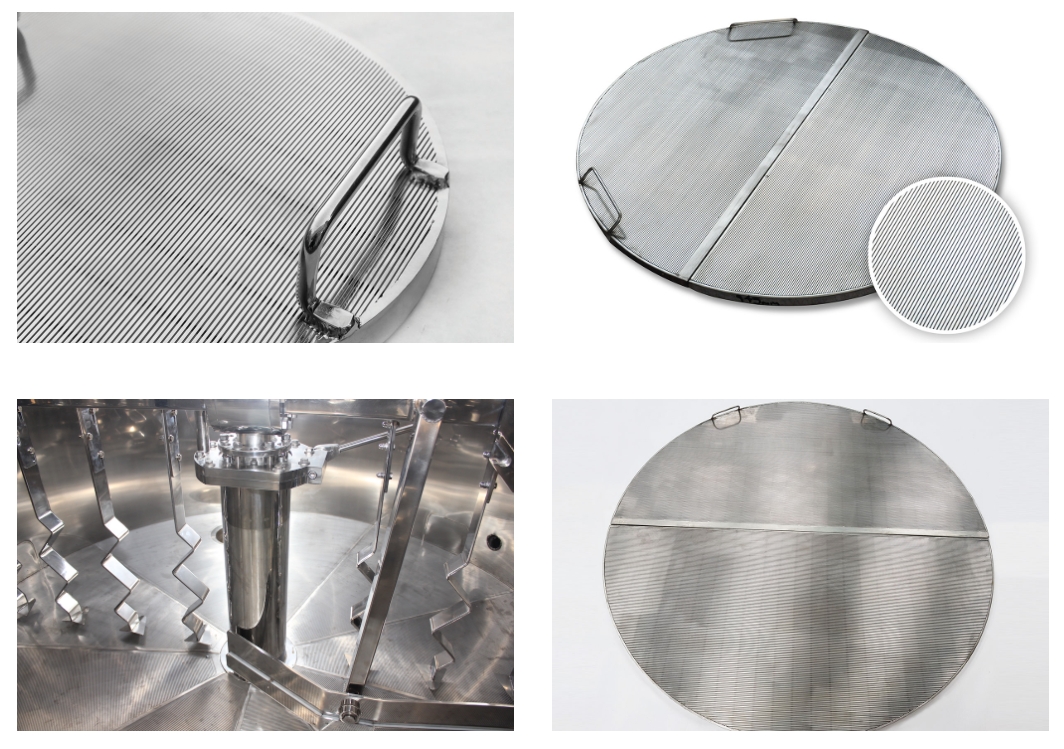

The Wedge Wire Screen mash tun Floors – a better filter screens in brewery filtration. Whitch is made from high-quality materials and precision-engineered to perfection, this mash tun Floors offers unparalleled performance and efficiency.

Unlike traditional perforated plates, wedge wire screen mash tun Floors boast superior filtration capabilities, ensuring swift drainage and crystal-clear runoff with minimal husk residue. The unique design of wedge wire screens prevents clogging and blinding, allowing for continuous operation without interruptions.

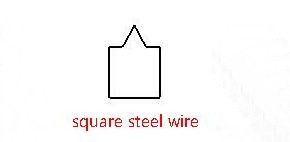

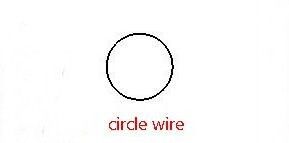

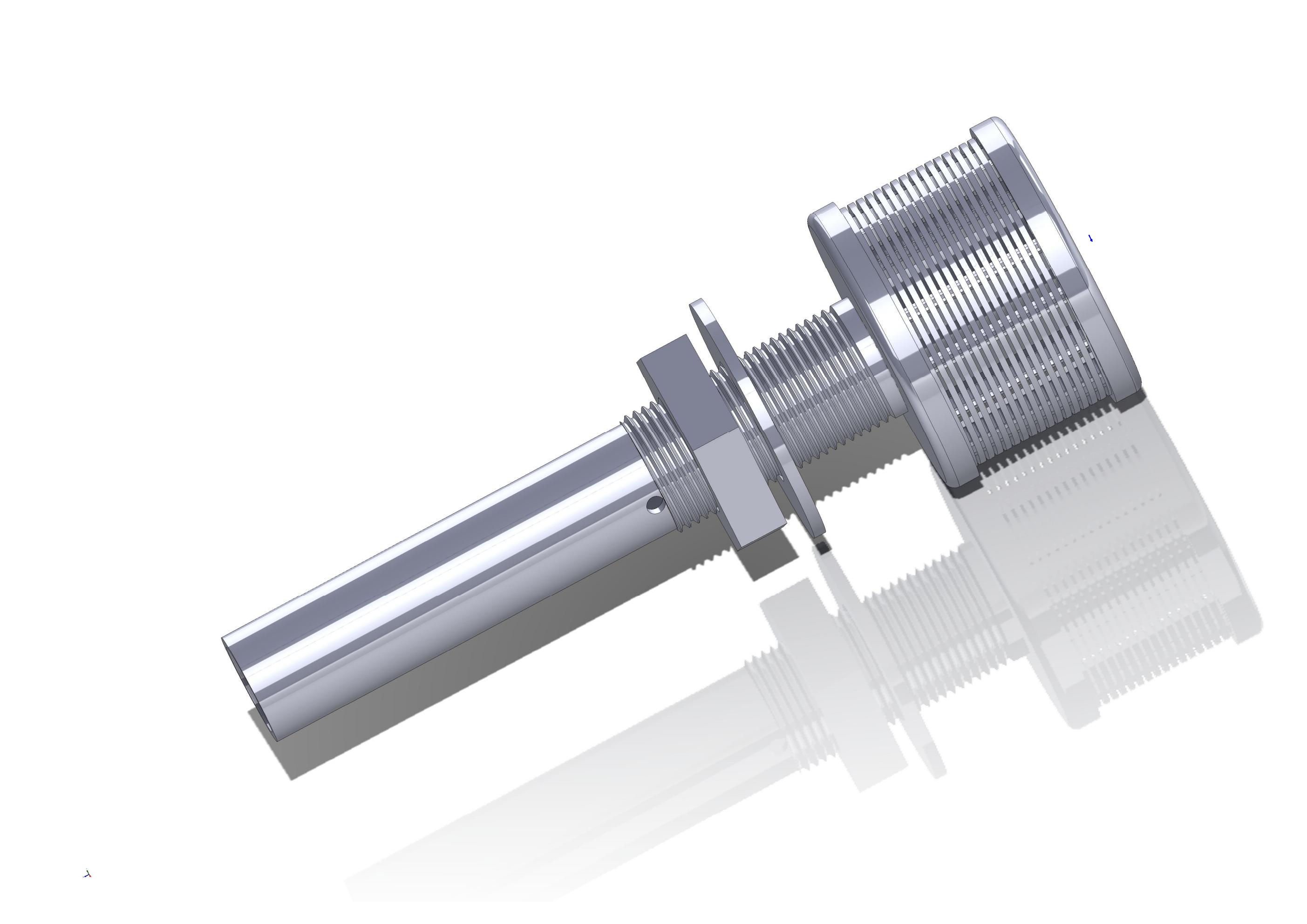

At YUANLV, whether you need circular or square floors, large or small sections for ease of cleaning, we have the expertise to deliver wedge wire screen mash tun Floors that perfectly integrate with your brewing setup.

Our wedge wire mash tun floors are not only highly efficient but also remarkably easy to maintain. Thanks to their self-cleaning properties, they require minimal upkeep, offering a cost-effective and hassle-free solution for breweries of all sizes.

Success Case:

A Canadian brewing company was using perforated plates for a mash tun floor client. However, he was having problems emptying the vessel, and the run off was not very clear. After installing the YUNALV wedge wire mash tun floor, the run off was quicker and also clearer with less husk.

This new wedge wire mash tun floor replaces a perforated sheet false bottom. The wedge wire is used at the bottom of the mash tun to cleanse and speed up the draining process.

Benefits Of Using Wedge Wire Screen

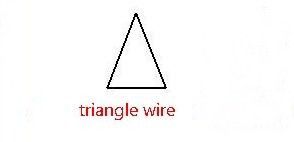

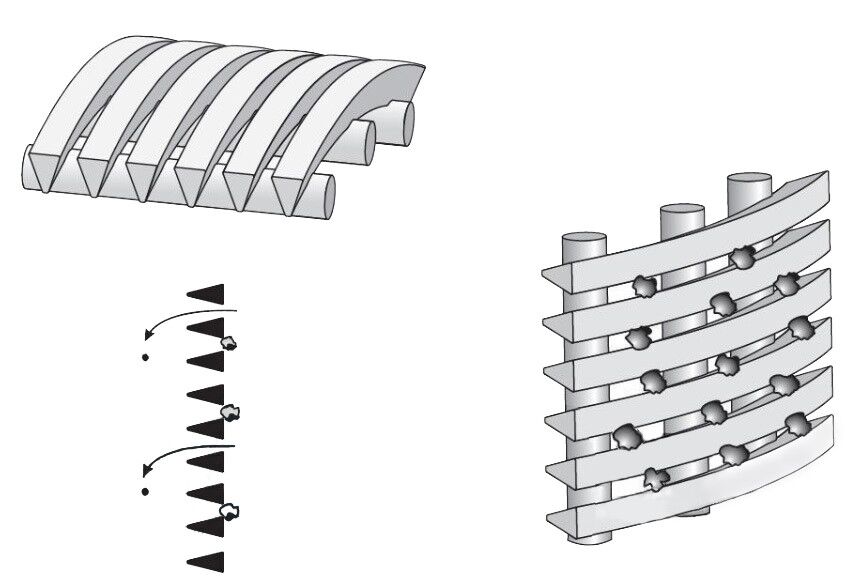

Wedge wire brewing mash tun false bottom floors consist of shape profile wire and longitudinal support rods. At each intersecting point the V shape section plane can avoid blockage, and make sure of the unimpeded water.

The milled area of the wedge wire mash tun screen are more continuous open area and precise slots, which can guarantee correct filtration. Correct filtration is extremely important in order to prevent the husks from passing through to the subsequent boiling phase, so that prevent bitter substances from being released into the beer.