Revolutionize Your Irrigation System with Self-Cleaning Filters

Achieving maximum yields from your land while keeping costs in check is a formidable challenge. The scarcity of high-quality potable water sources has pushed the utilization of reclaimed water and non-potable fresh water to the forefront. However, these alternative water sources often come laden with clogging agents, necessitating advanced irrigation and filtration systems. As labor costs surge globally, optimizing your resources becomes increasingly demanding.

Agricultural irrigation systems, just like the crops they nurture, demand meticulous maintenance. Moreover, with high-quality potable water sources becoming scarcer, reclaimed water and non-potable fresh water sources, including well water, have become go-to options for agricultural irrigation. Unfortunately, these water sources often carry a medley of clogging culprits such as sand, silt, clay particles, and organic matter.

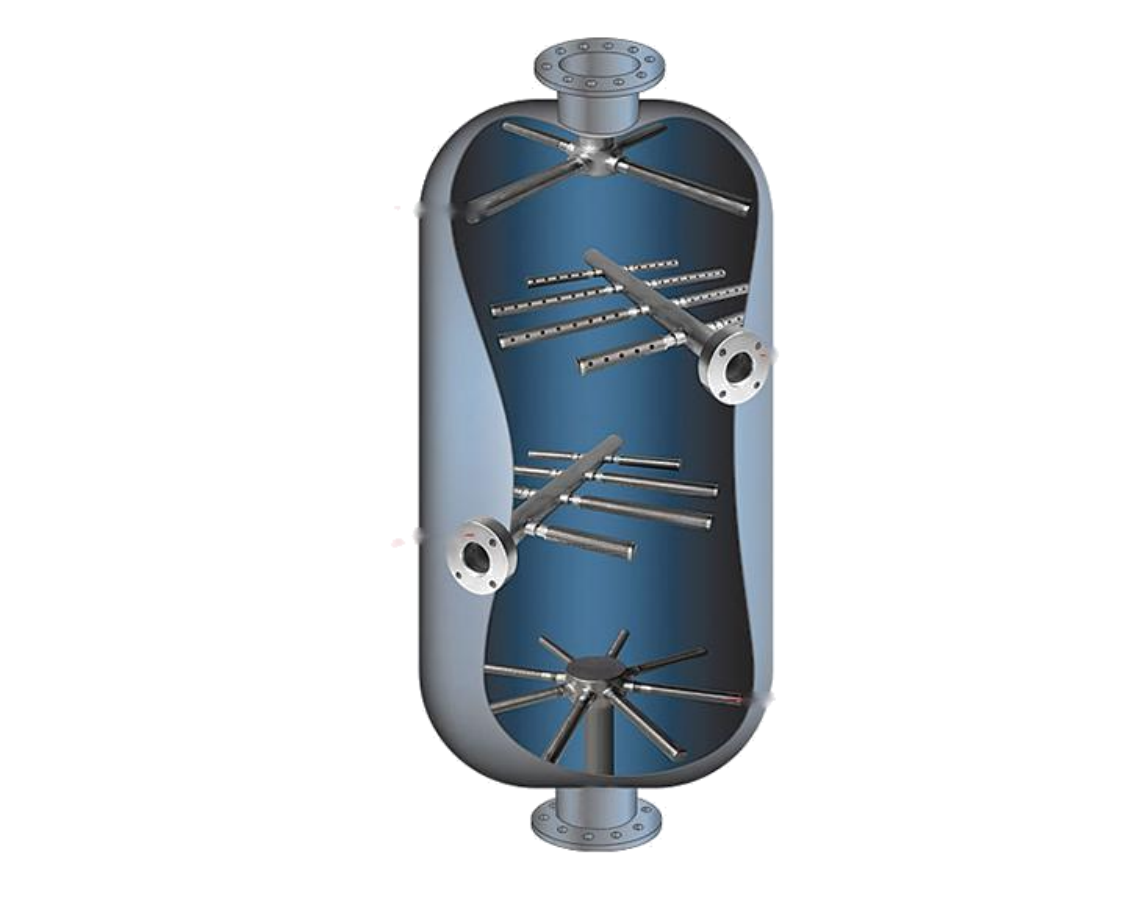

The manual upkeep and cleansing of your filtration system consume valuable time and labor. However, there's a solution – automatic self-cleaning agricultural irrigation filters.

These filters not only save time and manpower but also excel in water efficiency. They use precisely the required amount of water, eliminating wastage on manual flushing and cleaning. Consequently, both labor and water costs are slashed.

In essence, managing the cleaning and maintenance of your filtration system is a significant task, but a self-cleaning filter can shoulder this burden for you.

What Benefits Do Self-Cleaning Filters Offer?

Self-cleaning filters present a host of advantages to growers, landscapers, and farmers:

--Water Efficiency: They utilize the exact amount of water needed precisely when cleaning is required, optimizing water usage.

--Cost-Effective: Reduced water consumption translates to lower costs compared to manual cleaning and flushing.

--Labor Savings: With automatic self-cleaning, there's no need for manual labor to maintain and clean the filters, resulting in reduced labor expenses.

--Continuous Filtration: The filtration process continues without interruption during the cleaning cycle, ensuring a consistent water supply for your crops.

Furthermore, self-cleaning filters grant you the gift of time, allowing you to focus on the myriad other aspects of tending to your land. No longer do you need to fret about whether your filter requires cleaning or not, providing peace of mind.

Frequently Asked Questions

Which water sources are used for agricultural irrigation?

High-quality water sources for agricultural irrigation are becoming increasingly limited and costly. This has led to the adoption of more cost-effective and accessible alternatives, such as reclaimed water and non-potable fresh water, including well water.

Are self-cleaning screen filters more economical?

Absolutely! Manual filter maintenance and cleaning are labor-intensive and time-consuming. Automatic self-cleaning irrigation filters not only save time and labor costs but also use water efficiently, reducing overall expenses.

Can self-cleaning screen filters be customized?

Certainly! Each soil type and water source for agricultural irrigation has its unique characteristics and requirements. Self-cleaning screen filters can be tailored to your specific needs and the demands of your irrigation system.

Are you a filter factory or manufacturer?

Yes, YUBO is an industry filter housings and filter elements manufacturer in China, with our own manufacturing facility in China. Our team includes dedicated sales professionals and experienced engineers, ensuring top-quality products and services.