Profile Wire, or wedge wire, allows high precision and efficiency in screening applications. The wedge shape of the Profile Wire provides a large opening for material to flow between the wires.

In countless industrial, agricultural, and architectural applications, effective screening and separation are critical. Traditional methods like wire mesh, perforated plates, or filter cloths often fall short, plagued by issues like clogging, low flow rates, and frequent replacement needs. If you're looking for a smarter, more robust solution, it's time to explore the Profile Wire Screens, also known widely as Wedge Wire or V-Wire Screens.

What is Profile Wire?

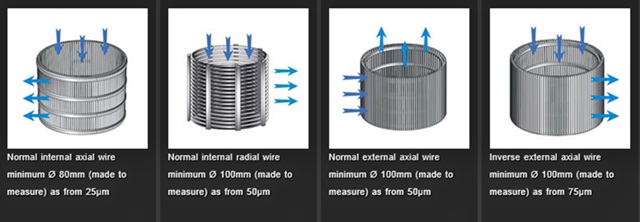

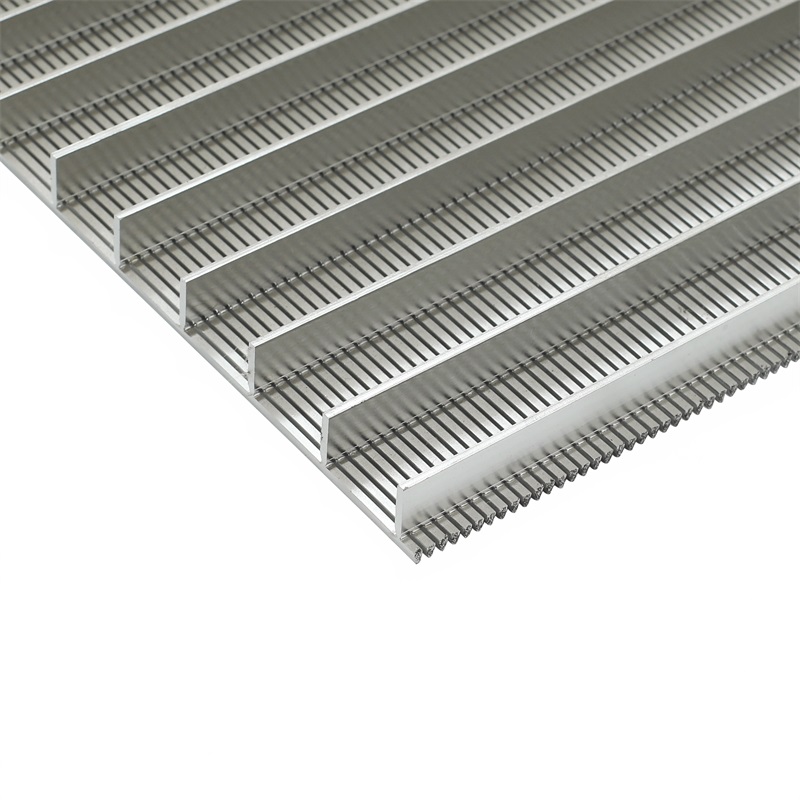

Profile wire screen, also called V wire screen, as the name suggests, is made by resistance welding V-shaped metal wire to the support rod; it has a smoother surface. From a structural point of view, this enables the V-wire screen to prevent clogging and make it have higher strength. Therefore, the profile wire screen has higher strength and durability than traditional wire mesh, porous plate, or filter cloth filters. According to the use environment and materials, it can be used for almost life without replacement, thereby reducing operating costs.

The genius of the profile wire screen lies in its geometry:

The V-Shape Advantage: The tapered "V" shape creates a narrow contact point on the screen's surface but immediately widens inwardly. This design allows particles smaller than the slot opening to pass through easily with minimal contact.

Continuous Slots: Unlike woven mesh or perforated plates, the slots run continuously along the screen's length or width, offering a significantly larger open area for efficient material flow.

Robust Welded Structure: Resistance welding fuses the V-wires and support rods into a single, incredibly strong and rigid unit.

Unpacking the Key Features and Tangible Benefits

This unique construction translates directly into significant operational advantages:

Exceptional Screening Efficiency & Precision: The large, uninterrupted open area created by the profile wires dramatically increases throughput. Material flows freely, allowing for faster processing and highly accurate sizing or separation based on the precise slot openings.

Superior Non-Clogging Performance: This is where profile wire truly shines. The V-shaped slots minimize the risk of near-size particles getting stuck (pegging) or fine materials blocking the openings (blinding). As material flows, the widening gap encourages particles to clear, leading to a virtually self-cleaning effect and consistent performance with minimal downtime.

Unmatched Strength and Durability: Compared to conventional screening media, the welded structure of profile wire screens offers vastly superior strength and rigidity. They can withstand demanding conditions, heavy loads, and abrasive materials far better than woven mesh or filter cloths.

Extended Service Life & Reduced Costs: Built to last, profile wire screens often provide service for extended periods, sometimes considered nearly lifetime components, depending on the application and material choice. This longevity drastically reduces replacement frequency, maintenance needs, and overall operating costs, delivering significant long-term savings.

Smooth Surface for Optimal Flow: The smooth operational surface minimizes friction and allows materials (solids or liquids) to move across and through the screen with less resistance, further boosting efficiency.

Diverse Applications: Where Profile Wire Excels

The versatility and high performance of profile wire screens make them the ideal choice across a wide spectrum of industries and applications:

Mineral Processing: Ideal for vibrating screen decks, dewatering screens, and classifying minerals due to durability and efficiency.

Water Treatment & Intake: Used extensively for surface water intake screens, preventing debris entry while ensuring high flow rates. Critical for fish diversion screen panels and hatchery screens, protecting aquatic life while maintaining water flow.

Food & Beverage Processing: Suitable for cross-flow sieves, filtration, dewatering, and drying applications (like flooring for malt kilns, germination beds, and grain drying) – often available in food-grade stainless steel.

Chemical & Petrochemical: Used in reactor internals, catalyst support grids, and various filtration processes.

Pulp & Paper: Effective in pulp screening and water straining applications.

Architecture & Design: Utilized for decorative grilles, flooring, facade elements, and custom screening solutions where both function and aesthetics matter.

The Smart Choice for Modern Screening Needs

If your operation demands high efficiency, precise separation, minimal downtime, and long-term value, profile wire (wedge wire) screens present a compelling solution. Their unique V-wire construction tackles the inherent weaknesses of traditional screening methods, offering unparalleled performance in flow rates, anti-clogging capabilities, and structural integrity.

Specifications:

Profile wire screen | |

Material: | Low carbon, low carbon galvanized steel (LCG), steel treated with plastic spraying, stainless steel (304, 316, 316Letc.) |

Wedge Wire (mm): | Width: 1.50 1.80 2.30 3.00 3.30 3.70 |

Height: 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 | |

Support Rod (mm): | Width: 2.30 3.00 3.30 3.70 |

Height: 2.70 3.60 4.70 5.60 6.30 | |

Round: 2.50mm -- 6.0mm | |

Width: | from 1 inch --45 inch. |

Length: | lengths up to 6 meters. |

Slot size: | 0.10, 0.15, 0.20, 0.25, 0.30,....., 3.00 also achieved upon request. |

Note: Other specifications can be customized according to your requirements | |