In the modern food processing industry, ensuring the cleanliness and safety of food is crucial.

Wedge Wire is used in the food and beverage industry for its high processing performance and handling qualities. Wedge Wire Food Beverage Applications are self-cleaning, low maintenance, and cost-effective for separating valuable liquids/solids.

Brewery Industry

YUBO proudly supplies premium wedge wire screen products designed specifically for the brewery industry.

Our offerings include:

1. Lauter Tun Screens

At YUBO, we manufacture top-quality lauter tun screens for breweries, distilleries, and wineries, playing a crucial role in the lautering process. Crafted from durable stainless steel wedge wire, our screens come in both customizable and standard slot sizes, delivering unmatched strength, reliability, and performance during this critical production stage.

The lauter tun screen acts by utilizing the mash's solid particles as a natural filter medium to separate the wort. Although the slots in the false bottom do not directly filter, they provide robust support for the grain bed, allowing efficient filtration by trapping solids and permitting wort flow. Precision-engineered construction ensures uniform and efficient filtration, preventing unwanted elements from compromising the taste and quality of beer, wine, or spirits.

Key benefits of YUBO's lauter tun screens:

High open area design for maximum wort extraction efficiency.

Available as single-piece units or modular sections for easy installation and maintenance through access points.

Enhanced operational flexibility and superior filtration performance.

2. Candle Filters

Candle filters from YUBO are indispensable for fine filtration and impurity removal in the brewing industry, ensuring superior product clarity and stability.

Their versatile applications include:

Beer Filtration: Eliminates yeast, bacteria, and particles to enhance clarity and shelf stability.

Wine Filtration:Improves taste and appearance by removing suspended solids.

Juice Filtration: Purifies juices by clearing solid impurities for a pristine appearance.

Liquid Refining:Ensures purity in refining spirits and distilled alcohol.

Microbial Control: Reduces contamination risk to improve product safety and longevity.

Sugar Industry

YUBO offers cutting-edge wedge wire screen solutions tailored for the sugar industry.

Our specialized products include:

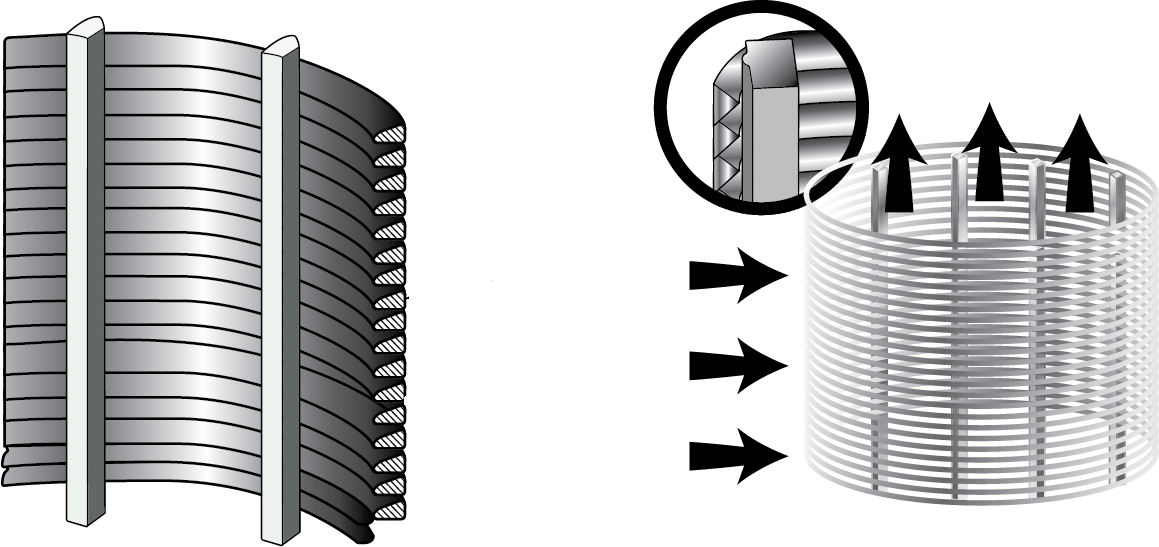

1. Centrifuge Baskets

The centrifuge basket plays a pivotal role in sugar production by separating molasses from sugar crystals.

YUBO's high-performance centrifuge baskets are designed to:

Enhance Molasses Separation: Efficiently separates residual molasses from sugar, maximizing sugar recovery.

Optimize Sugar Extraction: Rapid spinning action separates sugar crystals and solids from liquids, improving juice purity and refining efficiency.

Boost Production Efficiency: Reduces sugar loss, enhances molasses separation, and increases throughput.

YUBO's centrifuge baskets are engineered with advanced technology and precision craftsmanship to ensure consistent, high-quality performance and improved operational efficiency.

2. Filter Nozzles

Our filter nozzles are widely utilized in sugar juice and syrup filtration, supporting purification processes and equipment cleaning.

Key applications include:

Sugar Juice Filtration: Removes solid impurities to enhance juice purity.

Lime Water Filtration: Filters sediment from lime water used to neutralize acidic impurities.

Equipment Cleaning: Delivers high-pressure spray cleaning to remove sugar residues.

Sugar Refining: Eliminates fine particles to produce crystal-clear, high-quality sugar.

Water Treatment: Treats wastewater to meet environmental discharge standards.

YUBO's filter nozzles are customizable in size, design, and material, ensuring optimal performance tailored to each production environment.

Starch Industry

YUBO provides specialized wedge wire screen products designed to meet the unique filtration needs of the starch industry.

Our offerings include:

1. Pressure Screens

Pressure screens are vital for starch production, where they ensure impurity-free starch slurry.

Key benefits and applications:

Slurry Filtration: Removes insoluble fibers and proteins, producing cleaner starch.

Increased Starch Yield: Minimizes waste while enhancing starch recovery.

Enhanced Product Quality: Delivers higher starch purity and transparency.

Water Reuse: Filters solids from wastewater, enabling recycling and cost reduction.

Operational Efficiency: Minimizes blockages and wear, stabilizing production lines.

Features of YUBO pressure screens:

Extended Service Life: Reversible screens allow wear to be distributed, doubling lifespan.

Precision Slot Accuracy: Guarantees exact slot dimensions for superior filtration.

2. Gravity Screens

Gravity screens from YUBO effectively separate impurities and moisture using natural settling principles.

Key uses include:

Impurity Removal: Eliminates larger particles like soil and stones to enhance starch purity.

Preliminary Screening: Pre-filters raw materials to increase processing efficiency and reduce equipment strain.

Moisture Separation: Enhances dewatering and slurry quality by separating excess moisture.

YUBO's gravity screens deliver robust performance, reliable impurity separation, and improved production efficiency, meeting the highest industry standards.