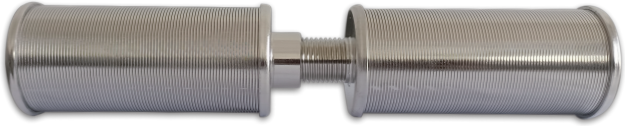

The hydration reactor 904L filter nozzle is the key internal part of the refining enterprise's methyl ethyl ketone device.

Our factory provides the 904L filter nozzle which is structured as a specification of φ45 OD Johnson mesh, with filtration precision of 0.2 (±0.02) mm.

METHYL ETHYL KETONE PLANT SBA HYDRATION REACTOR 904L FILTER NOZZLE

The hydration reactor wedge wire 904L filter nozzle is the key internal part of the refining enterprise's methyl ethyl ketone device, due to the complex working conditions of the filter medium and serious corrosion, needs to withstand the impact of large differential pressure, almost every year a certain number of officer nozzles will be replaced to ensure the normal and smooth operation of the methyl ethyl ketone device.

After nearly three years of unremitting efforts, our company has successfully launched our stainless steel 904L filter nozzle products by constantly collecting and mastering the environmental data of the hydration reactor process medium, seriously studying and exploring the manufacturing process of the 904L filter nozzle.904L filter nozzle is structured as a specification of φ45 OD Johnson mesh,with filtration precision of 0.2(±0.02)mm and inner and outer

threaded screwed connections.

The structure of the 904L filter nozzle is φ45 outer diameter Johnson mesh with 0.2mm filtration precision.

Standard slot width mm |

0.10 |

0.20 |

0.25 |

0.30 |

0.50 |

.... |

Advantages:

• Suitable for Ion exchange columns with double chamber

• For pharmaceutical, food, drink, and water treatment industries

• High-temperature resistance

• Long life and high resistance to corrosion

• Easy customization of the nozzle with pressure loss control

We are the 904L water filter nozzle manufacturer.

We can customize products and produce and export them directly, saving intermediate costs and time, helping more industrial factory plants achieve maximum profits, and ensuring accurate filtration.

If you have any questions, please don't hesitate to reach out for consultation.

Email: admin@yuanlvfilter.com

Mobile/WhatsApp/WeChat: 86-18032153916