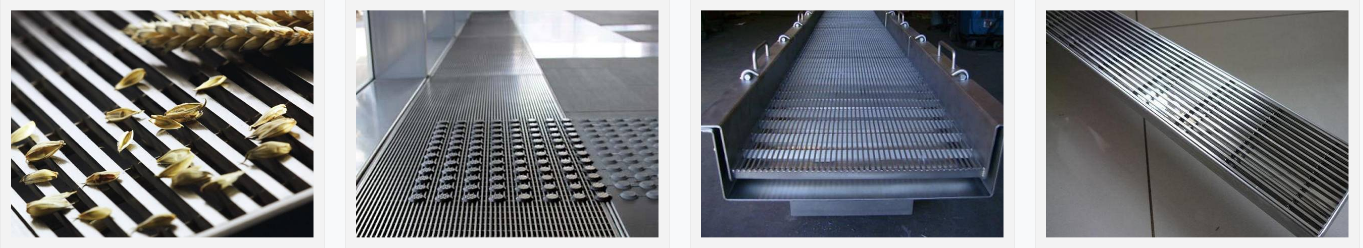

In the intricate web of industrial systems, the potential intrusion of foreign contaminants poses a constant threat. To safeguard the integrity and functionality of these systems, the deployment of high-quality filter strainers becomes imperative.

Among these, conical filter strainers execute crucial roles in maintaining system purity.

This article delves into the intricacies of conical strainers, exploring their design, purpose, applications, advantages, and various types available in the market.

I. Understanding Conical Strainers:

A. Definition and Structure:

1. Conical filter strainers, also known as temporary strainers, feature a mesh cone designed to fit seamlessly within diverse systems.

2. These cone strainers(temporary strainers) play a pivotal role in ensuring the filtration of the system, preventing the entry of contaminants that could compromise system efficiency.

II. Purpose and Applications:

A. Cost-Effective Straining Solutions:

1. Conical strainers prove to be cost-effective solutions in a myriad of applications.

2. Their ability to provide extensive filtration area makes them particularly adept at capturing debris and contaminants.

B. Welding Process Application:

1. Conical strainers excel in applications where welding processes might introduce slag or debris into pipes.

2. By capturing these particles, conical strainers prevent damage to delicate and expensive systems.

C. Industry-Wide Application:

1. Conical strainers find applications across diverse industries, including chemical processing, petroleum, power generation, and marine.

2. Common uses include protecting downstream components from damage caused by sand, gravel, or other unwanted debris in water-handling applications.

D. Versatility in Gas Applications:

1. Conical strainers extend their utility to air and natural gas applications, handling high pressures with ease.

III. Advantages of Conical Strainers:

A. Material Variability:

1. Conical strainers are available in various materials, offering flexibility to cater to specific industrial requirements.

2. Stainless steel and other materials ensure compatibility with different environments.

B. Enhanced Filtration Area:

1. The design of conical strainers, with a wide-to-narrow configuration, significantly increases the filtration area.

2. This design choice optimizes the strainer's ability to capture a higher volume of contaminants.

C. Flexible Placement:

1. Conical strainers can be strategically placed both upstream and downstream, depending on the unique demands of the application.

2. This flexibility enhances their adaptability to diverse system configurations.

D. Maintenance Considerations:

1. Regular inspection and cleaning are crucial to ensuring the optimal performance of conical strainers.

2. The mesh of a conical strainer may be susceptible to ripping under strain, emphasizing the importance of routine maintenance.

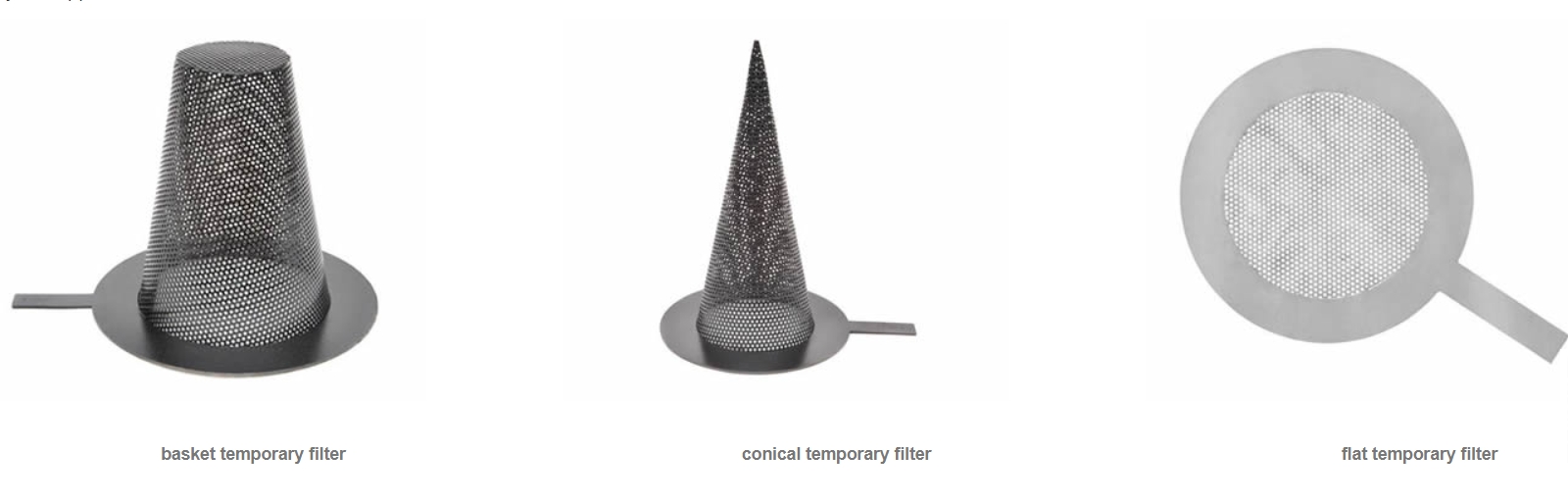

IV. Types of Conical Strainers:

A. Basket Temporary Filter

B. Conical Temporary Filter

C. Perforation Conical Types Temporary Filter

D. Flat Temporary Filter

V. Choosing the Right Conical Strainer:

A. Factors Influencing Selection:

1. System requirements.

2. Environmental considerations.

B. Consultation and Customization:

1. The importance of detailed requirements when inquiring about conical strainers.

2. How customization enhances satisfaction and performance.

VI. Conclusion:

Summarizing the critical role of conical strainers in maintaining system purity and efficiency.

Encouraging proactive maintenance and informed decision-making in selecting the right conical strainer for specific applications.

By providing a comprehensive overview of conical strainers, this article aims to serve as a valuable resource for industry professionals and decision-makers seeking effective solutions for system filtration and protection.

We are suppliers of Cone type temporary strainers in fully various designs. Please provide the detailed requirements when inquire to us. It will help to give a satisfactory answer.