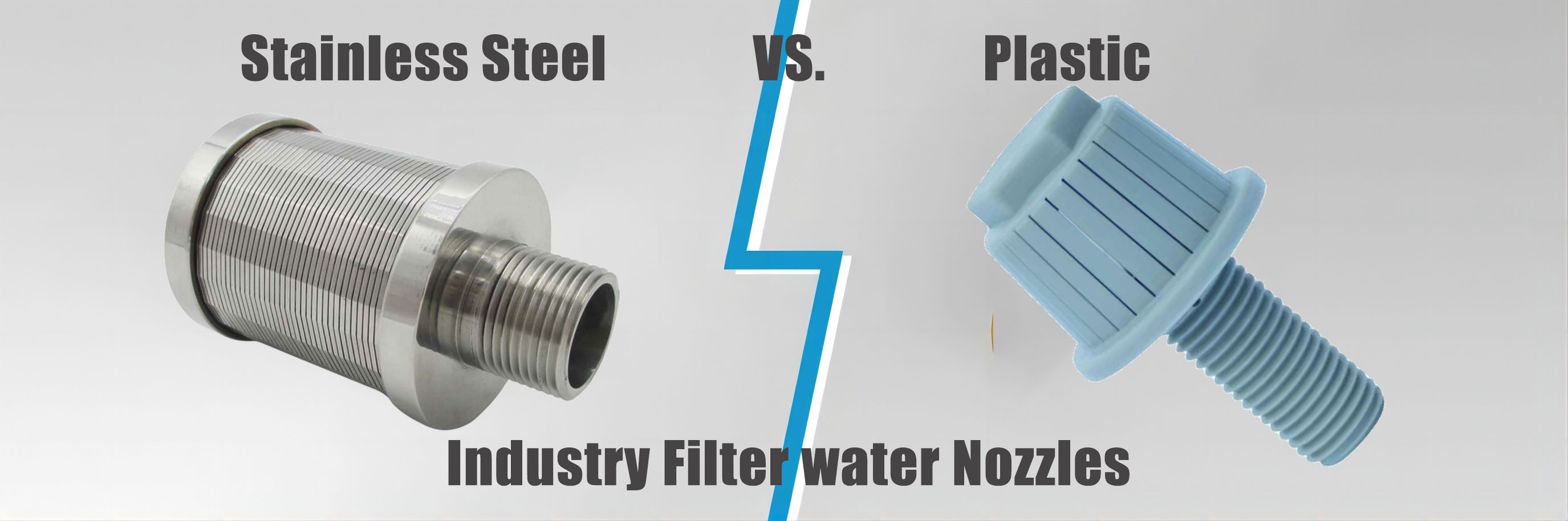

Selecting the ideal material for an industry water filter nozzle is pivotal for optimal performance and durability. The material's intrinsic qualities significantly impact the nozzle’s lifespan and functionality. Two primary contenders for industry water nozzle construction are stainless steel and plastic, each with distinct advantages based on specific application requirements.

Stainless Steel Water Nozzles:

Stainless steel, comprising iron, carbon, and alloying elements like chromium and nickel, offers remarkable hardness and resistance to erosion and chemical attacks. Variants like 304, 316, and 316L cater to diverse needs.

High Temperature Resistance:

Stainless steel thrives in high-temperature environments, enduring up to 500°C effectively.

Corrosion Resistance:

While robust, stainless steel exhibits varying corrosion resistance:

AISI 303: Good against atmospheric exposure and certain chemicals but weak against chlorides and high temperatures.

AISI 316/316L: Resistant to various salts and organic acids but susceptible to specific acids at elevated temperatures.

AISI 420/416: Suitable for drinkable water, steam, fuels, and alcohols.

Cost-Effectiveness:

In suitable environments, stainless steel nozzles offer cost-effective solutions.

Plastic Materials Water Nozzles:

Polymers like PVC, PP, and PVDF constitute thermoplastic nozzles, each with distinct temperature and chemical resistance properties. They are chosen based on compatibility with other components in the system.

Temperature Resistance:

Thermoplastics have low tolerance for high temperatures, leading to melting and deformation. Not recommended for high-temperature applications.

Corrosion Resistance:

Plastics excel in resisting corrosion and aggressive environments without additional protective measures.

Cost Efficiency:

Plastic nozzles prove cost-effective in highly corrosive conditions but might not offer savings in extreme heat or abrasion scenarios.

Considerations Beyond Stainless Steel and Plastic:

Apart from stainless steel and plastic, various metals and exotic materials cater to unique application needs.

Extending Nozzle Life:

Proper nozzle use and regular maintenance significantly prolong nozzle life, preventing quality issues and profit loss.

Tailored Solutions for Filter Nozzles:

For optimized filter performance, selecting nozzles designed to meet specific filter specifications is crucial. Options include material, mounting style, flow rate capacity, and tailpipes for air scour.

Get In Touch:

Reach out to us for guidance in selecting the ideal industry water treatment filter nozzle for your application. We offer an extensive range of custom water/wastewater treatment filter strainer products and filtration solutions. Contact us at 86-18032153916 or

When optimizing filter performance within a nozzle underdrain system, precise alignment of the nozzles with your filter specifications is paramount. Our range offers diverse design options encompassing material, mounting style, flow rate capacity, and tailored tailpipes for air scouring. We are confident in providing filter nozzles that align seamlessly with your unique requirements.

We boast the capability to replace any existing OEM design available in the market. Whether it involves offering a direct replacement or customizing and redesigning the nozzle, our goal remains consistent: ensuring peak filter performance is achieved. This adaptability allows us to guarantee an optimal fit and functionality, tailored specifically to your filtration needs.