The extraction of potato starch is a complex and cost-intensive process, demanding both efficiency and quality. In starch production, conserving fresh water and energy is crucial, alongside the goal of achieving high starch purity. YUBO Filter offers advanced industrial self-cleaning filter housing and candle filter solutions designed to enhance productivity while reducing operational costs.

Our self-cleaning filters are purpose-built for the automatic filtration of water in potato starch production. YUBO Filter's robust design ensures reliability and dependability, making it ideal for applications where process integrity is paramount. These filters provide precise filtration down to an impressive 35 micrometers (µm).

Did you know?

Through an automated process, starch is extracted from potatoes, with water filtered down to 35 micrometers (µm). Notably, one of our customers experienced a 15% increase in production and significantly reduced maintenance by adopting our Auto inline self cleaning filter.

Modern potato starch production involves well-defined processes, mainly distinguished by effluent requirements and the necessity to recover protein to reduce BOD (Biochemical Oxygen Demand) load. YUBO Filter offers a comprehensive range of filter products and filtration systems for potato starch production, characterized by high reliability, low operational costs, and outstanding performance.

Fruit Water Removal

Efficiently removing fruit water at the beginning of the process improves starch quality and enables the recovery of proteins as valuable by-products. Our wedge wire centrifuge baskets deliver high dry solids percentages, increased capacity, and minimal maintenance requirements. A higher dry solids percentage reduces impurities to be washed off during starch washing, consequently lowering water consumption.

Starch Extraction

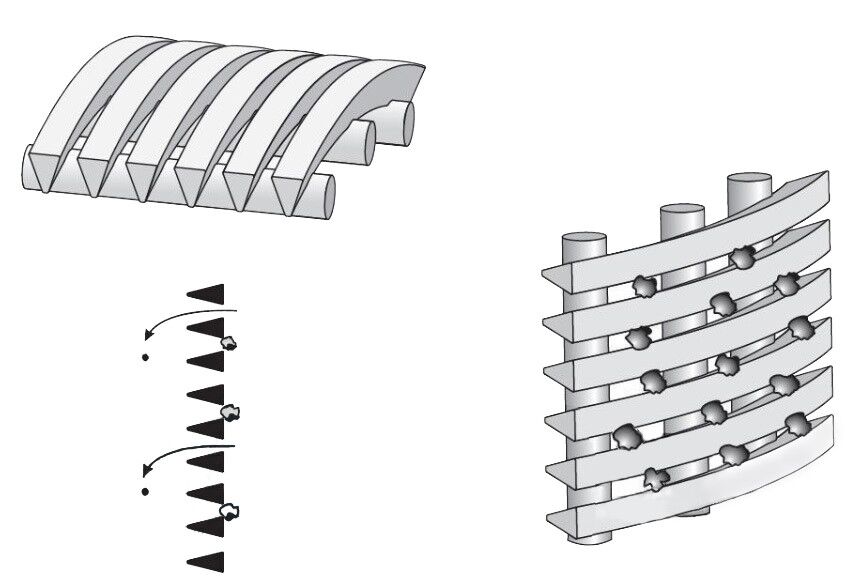

Wedge wire sieve screens are employed for effective fiber removal. Each screening centrifuge comprises a rotating conical basket with sieve plates, a continuous spray nozzle arrangement for washing over the pulp layer, a housing equipped with nozzles for sieve "backwashing" and housing cleaning, and a reliable drive arrangement.

Pre-Concentration

Self-cleaning filter housings are perfectly suited for potato starch production, offering maximum separation efficiency, precise control, minimal clogging, and easy maintenance.

Starch Washing

Candle filter housings, known for their high performance and dependable operation, facilitate efficient washing and yield exceptionally low impurity levels in the final product.

Protein Precipitation and Recovery

Fruit water is processed in a separate line, featuring a regenerative spiral heat exchanger system for protein coagulation, followed by a decanter centrifuge for efficient separation and recovery of coagulated proteins.

Additional Equipment

YUBO provides an extensive range of equipment for use in starch processing, including strainers and degritting systems.

Tailored Solutions for Specific Processes

Our filtration solutions and filters for potato starch production are adaptable to meet individual customer process requirements.

Interested in Learning More About Our Potato Starch Extraction Solutions?

Feel free to reach out to our starch filter experts through our contact form. With over 15 years of experience in developing filtration solutions for various industries, we eagerly await your special requests and inquiries.

Contact US Now