Exploring the Advantages of Wedge Wire Intake Screens for Efficient Water Filtration

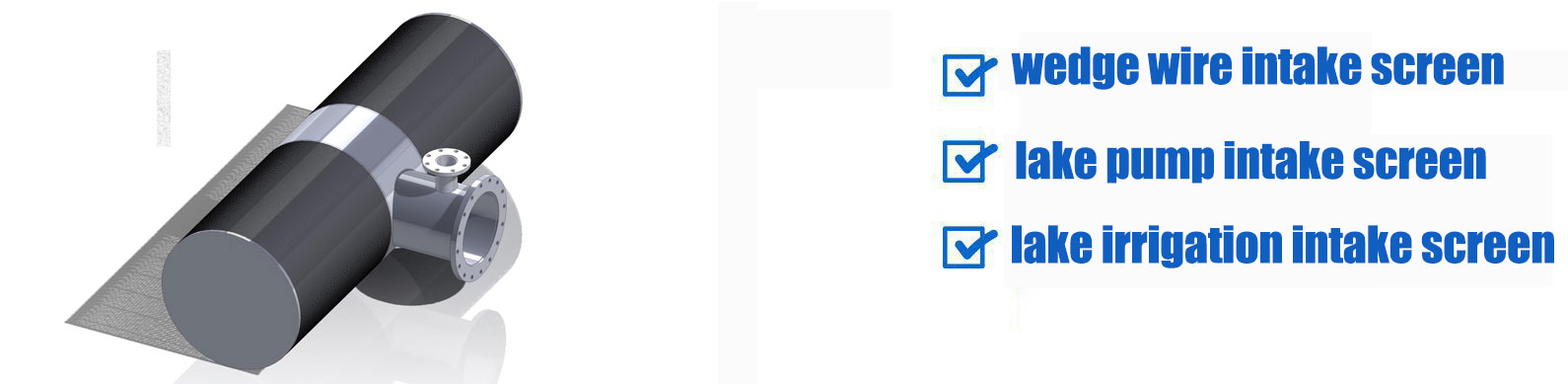

Water intake screens are critical components in lake irrigation systems, designed to prevent debris, aquatic organisms, and other contaminants from entering the irrigation network.

In today's fast-paced world, ensuring access to clean and safe water is of paramount importance. Water intake systems play a crucial role in filtering out debris and impurities to maintain the quality of water for various industrial and municipal applications. One technology that has gained popularity due to its efficiency and reliability is the Wedge Wire Intake Screen. In this blog post, we will delve into the features and benefits of this innovative filtration solution, exploring why it is becoming the go-to choice for water intake applications.

What is Wedge Wire Water Intake Screens?

Wedge Wire Intake Screens are cylindrical, curved, or flat panels designed with precision V-shaped wires that create narrow slots. These screens are engineered to remove solids from water streams efficiently while allowing uninterrupted water flow. The distinct wedge-shaped wires offer a higher open area and better particle retention, making them ideal for various water intake processes.

Water Intake Screens Key Advantages

1. Superior Filtration Efficiency: The unique V-shaped profile of the wedge wire provides exceptional filtration capabilities, ensuring the removal of both large and small particles, sediment, algae, and other impurities from the water source.

2. Minimal Clogging and Downtime: Thanks to their design, wedge wire intake screens are less prone to clogging compared to traditional mesh filters. This leads to reduced downtime, lower maintenance costs, and increased overall productivity.

3. Robust Construction: Wedge wire screens are made from high-quality stainless steel, making them highly durable and resistant to corrosion, ensuring a longer lifespan even in harsh environments.

4. Flexible Design Options: Wedge wire intake screens can be custom-engineered to fit specific project requirements, enabling adaptability to various intake systems and configurations.

5. Environmentally Friendly: With their high filtration efficiency and reduced need for chemical treatments, wedge wire intake screens contribute to eco-friendly water management practices.

The Crucial Role of Water Intake Screens in Lake Irrigation: Ensuring a Sustainable Water Supply

Lake irrigation is a sustainable water management practice that involves harnessing the water from natural or artificial lakes to meet various demands. This method reduces the dependence on groundwater and ensures a consistent supply, even in drought-prone regions. However, the quality of water drawn from lakes can vary significantly, necessitating efficient filtration mechanisms.

Water intake screens are critical components in lake irrigation systems, designed to prevent debris, aquatic organisms, and other contaminants from entering the irrigation network. These screens act as the first line of defense, ensuring that only clean and clear water reaches the irrigation infrastructure.

The Importance of Lake Irrigation Intake Screens:

Protecting Equipment and Infrastructure: Debris and sediments present in lake water can cause significant damage to irrigation pumps, valves, and pipelines. Lake irrigation intake screens prevent clogging and wear on these essential components, extending their lifespan and reducing maintenance costs.

Enhancing Water Quality: By filtering out leaves, twigs, algae, and other impurities, intake screens improve water quality, reducing the need for additional chemical treatments. This not only benefits crops and plant life but also ensures the sustainability of aquatic ecosystems.

Sustainable Water Management: Lake irrigation intake screens contribute to responsible water usage by maximizing the efficiency of water extraction. By ensuring that water is drawn in a controlled and filtered manner, intake screens help preserve lake ecosystems and maintain a balanced water level.

Types of Lake Irrigation Intake Screens:

Traveling Screens: These screens are continuously moved across the water surface, trapping debris and contaminants as they pass through the water intake.

Wedge Wire Screens: Wedge wire intake screens, as discussed in our previous blog, offer superior filtration efficiency and durability, making them an excellent choice for lake irrigation systems.

Lake Irrigation Intake Screens Quote

Other Applications of Water Intake Screens

Municipal Water Treatment: Wedge wire intake screens play a vital role in municipal water treatment plants, safeguarding water quality by preventing debris from entering the water supply.

Industrial Water Intake: Industries such as power generation, chemical processing, and mining rely on wedge wire intake screens to protect equipment and machinery from damage caused by debris in water sources.

Aquaculture and Fish Protection: In aquaculture operations, these screens are used to maintain optimal water conditions while ensuring the protection of fish and other aquatic life.

Desalination: Wedge wire intake screens aid desalination plants by removing impurities from seawater, improving the efficiency of the desalination process.

In the pursuit of sustainable water management, lake irrigation has emerged as a viable solution to meet the ever-growing water demands. However, the success of this method relies heavily on effective water intake screens. By protecting equipment, enhancing water quality, promoting sustainable practices, and mitigating environmental impact, these screens play a crucial role in the efficient operation of lake irrigation systems.

Wedge wire intake screens have revolutionized water filtration in various industries, delivering unparalleled efficiency, longevity, and adaptability. Their innovative design and superior performance make them an attractive choice for water intake systems worldwide. With advantages like minimal clogging, reduced maintenance costs, and eco-friendly operations, these screens are set to shape the future of water treatment and contribute to a sustainable water supply for generations to come. Embracing this technology promises to enhance water management practices, safeguard public health, and protect vital ecosystems. Invest in the power of wedge wire intake screens today, and secure a cleaner, safer tomorrow.