Self-cleaning filters are mainly used in the following stages of the beer industry: beer canning line bottle washing system, beer puree wort filtration system, brewery cooling circulating water system, brewery raw water system and other sections.

YUBO will use different equipment in different filtration stages to play effectively for their excellent characteristics, Saving water resources and cost, improve working efficiency, promote factory to be more environmentally ,scientific innovation and development.

Fully automatic self-cleaning filter brewery circulating cooling water solution

The circulating cooling water of the brewery accounts for a large proportion of the production water of the beer industry. After long-term circulation of cooling water, scaling, corrosion and microbial growth will occur to a certain extent. Only by solving these three problems can we better improve economic benefits. YUBO recommends the use of fully automatic self-cleaning filters, which can effectively solve the above problems in the circulating cooling water system.

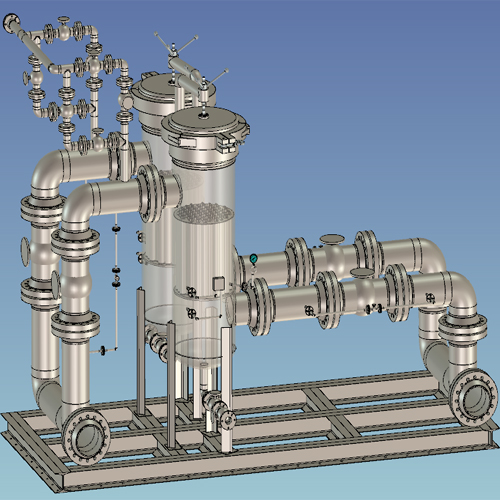

Self-cleaning filter is a kind of filtering equipment that uses filter screen to directly intercept impurities in liquid, such as floating matter, particulate matter and other substances, while reducing water turbidity, reducing dirt, and ensuring the normal operation of subsequent equipment. The self-cleaning filter has the feature of automatic sewage discharge. Raw water enters the filter from the water inlet, and first passes through the coarse filter element to filter out large particles of impurities, and then reaches the fine filter. After the small particles of impurities are filtered through the fine filter, the clean water is discharged from the outlet.

The circulating cooling water of the brewery is filtered using the working principle of the self-cleaning filter. During the whole process, it can quickly separate impurities in the water and play a very good role in protecting water resources.

YUBO is the self cleaing filters manufacturer in China, we can provide the high quality filter housings for you and design the drawing as your project application. More details, please contact us today, sales@ubofilter.com