Our cartridge filter housing also called cartridge filter vessel, offers a complete line of single cartridge filter housings and multi-cartridge filter housings for use in the clarification, sterilization, and high-efficiency filtration of liquids and gases.

our cartridge filter housing can be custom manufactured with the widest range of sizes, materials, and cartridge filter housing design options to exactly match your flow rate, pressure rating, and holding volume requirements, including 316 stainless steel cartridge filter housing, industrial cartridge filter housings, sock filter housing, single cartridge filter housing, multi-cartridge filter housing.

We have a full selection of water filter cartridges to use with our or other brands’ cartridge filter housings.

Compared to other cartridge filter housing manufacturers, our industrial cartridge filter housings deliver end-users a large variety of cartridge filter design choices for chemical compatibility and increased particle retention. Filson cartridge filter housings are ideal using in chemical systems, commercial RO and membrane water treatment systems, pharmaceuticals, cosmetics, food & beverage, industrial facilities…

With our’s know-how in the cartridge filter housing industry, we can help you save costs and remain competitive by being your OEM partner for stainless steel filter housing.

Whether for standard, custom, or different thicknesses, our cartridge filter housings provide a high-quality solution for all market needs.

It features a ring-nut closure, clamp closure, or bolt closure with a standard O-ring for quick, easy cartridge change-outs and secure sealing.

Flexible connections and adjustable-height legs allow the end-user to easily install the housings to new or existing limited space. Wall mounting brackets are available as well.

Our single cartridge filter housings are sold ready to install with all gaskets, o-rings, and parts.

And it allows full access to all cartridge filter vessel internal surfaces for easy cleaning with ss filter housing complete disassembly possibility.

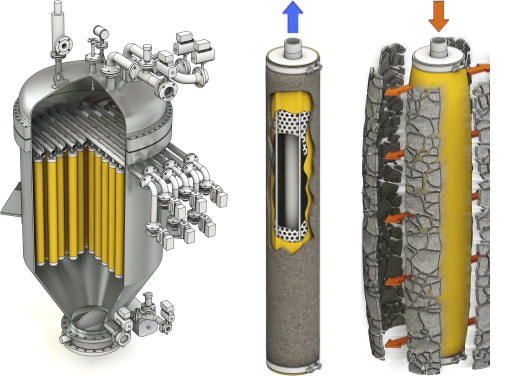

Our Multi-Cartridge Filter Housing or multi-cartridge filter vessel is an industrial water filter housing with a lightweight, externally polished stainless steel design.

It has superior flow capacities and contaminant holding capabilities with a wide variety and number of filter cartridges.

Our multi-cartridge filters provide outstanding durability and reliable performance across a variety of industrial and commercial applications.

It features including a swing bolt secured, quick opening cover, sealing plate, and an internal positive pressure cartridge alignment.

Constructed from 304, 316, or 316L stainless steel, Our multi-cartridge filter housings come with standard zinc plated bolts and legs.

Features of Cartridge Filter Housing

High-grade carbon, stainless steel 304, 316, 316 L construction

Crevice-free welding provides a smooth interior for easy cleaning

Standard features include vent, gauge ports, clean drain & dirty drain connections

T-Port/ In-Line/ Open/ L-Port choices for single cartridge filter housing

Flanged or threaded connection for multi-cartridge filter housings

Duplex is available for continual operation

Minimal pressure losses due to optimized flow patterns

The cartridge filter housing has a universal top seal plate for cup, spring, or fin style tops

Machined cover gasket groove provides positive O-ring sealing

Each cartridge filter housing get through factory hydro-tested

Custom possibilities for high-pressure/hot water applications

Single unit disassembly for easy cleaning and cartridge replacement.

All parts (except the o-ring) can be made of stainless steel for strength, durability, and chemical compatibility

Polished or sandblast exterior and pickle passivate interior/exterior for enhanced corrosion resistance

Cartridge Filter Working Principle

Unfiltered liquid enters cartridge filter housing and is distributed evenly around the water filter cartridges from outside to inside.

Solids are collected on the cartridges outside for easy removal.

The filtered liquid then exits through the outlet pipe of the cartridge filter housing.

Application of Cartridge Filter Housing

Potable Water

Process Water

Chemical

Oil and Gas

Food & Beverage

Pre RO water

Compressed air

Cosmetics

Coolants

Coatings

Solvents