Filtration in the food and beverage industry is a critical part. Filtration keeps foods fresher, prolongs a snack’s shelf life, keeps beverages from spoiling too soon, and helps our veggies to taste and smell more palatable.

Potable water is a critical ingredient in many foodstuffs such as reconstituted juices and is also used for washing and rinsing of vegetables, meats, etc.Safety first: Whatever beverage you produce – beer, wine, bottled water, soft drinks, or spirits - you cannot afford to compromise on quality.

Some of the more common beverages that rely on filtration technology include:

Wine Soda Beer De-alcoholization (for non-alcoholic beverages) Juice

watermark

Some of the more common foods that rely on filtration technology include:

1. Cheese and other dairy products2. Meat, fish, and their solid products (not including oils, fat, and juices)

3. Fruits and vegetables (not including oils, fat, and juices)

4. Oils and fatsGrains, cereals, and starches

5. Gelatin concentration

6. Corn wet milling

7. Xanthan gum

8. Maple syrup

9. Animal feed

10. A variety of dry and liquid separation processes are used in food and beverage production.

Below are a few common applications:

1. Salt production – Basket centrifuges are commonly used in salt production.2. Cream separation (from milk) – Disc centrifuges were designed for cream separation and still used to this day.

3. Water purification – Membranes are used to purify water before use as a food or beverage ingredient.

4. Wastewater treatment – Wastewater is treated at facilities.

5. Corn wet milling – A variety of filtration steps, including micro and nanofiltration, are required in the wet milling of corn. For example, filtration is used to remove microorganisms as well as to concentrate and clarify corn syrup.

6. Sugar juice and crystals – Rotary vacuum drum filters separate sugar juice from settled muds before a centrifuge is used to recover sugar crystals.

7. Vegetable seed oil refinement – Tubular or disc centrifuges and vacuum filters are commonly used to refine and de-wax vegetable seed oils.

8. Beer and spirits production – Numerous separation activities take place including separation and dewatering of grains and clarifying liquids.

How Filtration Benefits the Food and Beverage Industry?

1. Clarifying or trap filtration – Removes earth powders and particles as well as “polishes” the wine.2. Fine filtration – Removes yeast and is often used as a pre-sterilization process.

. Sterile membrane filtration – Removes spoilage organisms.

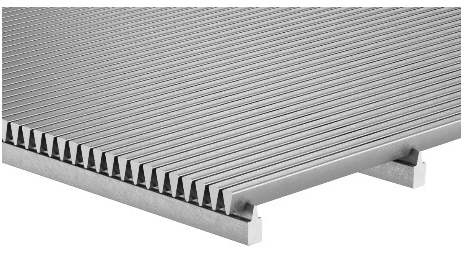

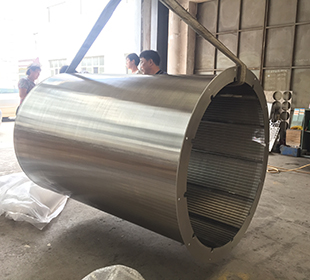

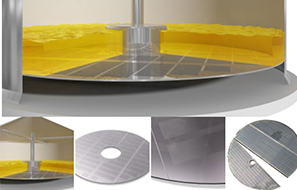

YUBO has several decades of experience in the food and beverage market and has developed a range of specific products, addressing filtration steps along the differing beverage industry process chains, offering filter solutions and filter element products.